Today's KNOWLEDGE share:

PET Vs PETG: THE MAIN DIFFERENCES

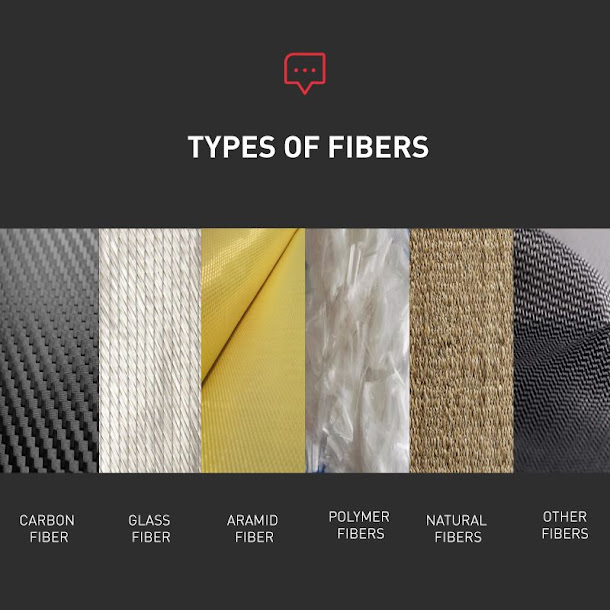

A basic formula for making polyesters, like PET and PETG, is the combination of acid monomers plus glycol monomers. In the case of PET, the acid is usually DMT (dimethyl terephthalate) and the glycol is ethylene glycol. These two monomers are the building blocks of the final long-chain polymer: polyethylene

terephthalate.

For creating PETG, the same monomers are used, except some ethylene glycol (30-60%) is substituted with a different glycol monomer, CHDM (cyclohexanedimethanol). So it’s not that PETG has significantly more or less glycol than PET, it just has a different type of glycol. Therefore, the -G in PETG represents the chemical modification of the typical PET structure with CHDM glycol units, or “glycol-modified” for short.

The key impact of this glycol modification from a physical standpoint is that semi-crystalline PET gets transformed into amorphous PETG. Let’s quickly review what crystallinity has to do with polymers and why its relevant to 3D printing.

In a few words, amorphous polymers have all their chains arranged randomly, much like a bowl of spaghetti. Semi-crystalline polymers contain regions of crystallinity where chains are highly-ordered and densely packed. This has an enormous impact on material properties.

Semi-crystalline materials are generally more rigid compared to a totally amorphous counterpart, as crystalline regions can function as reinforcement. This holds true for semi-crystalline PET and amorphous PETG.

While cooling, semi-crystalline materials are prone to warping caused by changes in density brought on by the formation of crystalline regions. This means amorphous PETG is much more manageable for 3D printing. Semi-crystalline PET, on the other hand, requires stricter printing and ambient temperatures to prevent distortions.

PET also has a slightly higher working temperature compared to PETG due to its crystalline nature. While this may make it more difficult to print with, PET will hold up better in applications that require some thermal resistance.

You may also notice visual differences between the two materials. The purely random nature of the polymer chains in PETG creates glossy or even transparent filaments. PET, as a mixture of crystalline and non-crystalline regions, will have some haziness.

Crystalline structures, like those of PET, don’t play well with extrusion. Crystallization is difficult to control and can begin as soon as the plastic is just a bit too cool. Manufacturers often facilitate extrusion using additives that hinder crystallization.

On the other hand, glycol modification of PET renders it an amorphous material that can easily be modeled via extrusion, injection molding, and other thermo-forming processes. This is the key to the success of PETG.

Source:all3dp

#3dprinting #plastics #pet #petg #molding