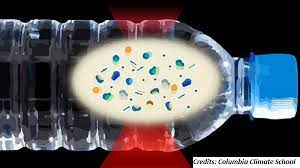

Using newly refined technology, researchers have entered a whole new plastic world: the poorly known realm of nanoplastics, the spawn of microplastics that have broken down even further. For the first time, they counted and identified these minute particles in bottled water.

They found that on average, a liter contained some 240,000 detectable plastic fragments—10 to 100 times greater than previous estimates, which were based mainly on larger sizes.

Yet to Discover Possible Effects on Human Body

Nanoplastics are so tiny that, unlike microplastics, they can pass through intestines and lungs directly into the bloodstream and travel from there to organs including the heart and brain. They can invade individual cells, and cross through the placenta to the bodies of unborn babies. Medical scientists are racing to study the possible effects on a wide variety of biological systems.

“Previously this was just a dark area, uncharted. Toxicity studies were just guessing what’s in there,” said study coauthor Beizhan Yan, an environmental chemist at Columbia Climate School’s Lamont-Doherty Earth Observatory. “This opens a window where we can look into a world that was not exposed to us before.”

Worldwide plastic production is approaching 400 million metric tons a year. More than 30 million tons are dumped yearly in water or on land, and many products made with plastics including synthetic textiles shed particles while still in use. Unlike natural organic matter, most plastics do not break down into relatively benign substances; they simply divide and redivide into smaller and smaller particles of the same chemical composition. Beyond single molecules, there is no theoretical limit to how small they can get.

Microplastics are defined as fragments ranging from 5 millimeters (less than a quarter inch) down to 1 micrometer, which is 1 millionth of a meter, or 1/25,000th of an inch. (A human hair is about 70 micrometers across.) Nanoplastics, which are particles below 1 micrometer, are measured in billionths of a meter.

110,000 to 370,000 Plastic Fragment in Each Liter

Plastics in bottled water became a public issue largely after a 2018 study detected an average of 325 particles per liter; later studies multiplied that number many times over. Scientists suspected there were even more than they had yet counted, but good estimates stopped at sizes below 1 micrometer—the boundary of the nano world.

“People developed methods to see nano particles, but they didn’t know what they were looking at,” said the new study’s lead author, Naixin Qian, a Columbia graduate student in chemistry. She noted that previous studies could provide bulk estimates of nano mass, but for the most part could not count individual particles, nor identify which were plastics or something else.

The new study uses a technique called stimulated Raman scattering microscopy, which was co-invented by study coauthor Wei Min, a Columbia biophysicist. This involves probing samples with two simultaneous lasers that are tuned to make specific molecules resonate. Targeting seven common plastics, the researchers created a data-driven algorithm to interpret the results. “It is one thing to detect, but another to know what you are detecting,” said Min.

The researchers tested three popular brands of bottled water sold in the United States (they declined to name which ones), analyzing plastic particles down to just 100 nanometers in size. They spotted 110,000 to 370,000 plastic fragment in each liter, 90% of which were nanoplastics; the rest were microplastics. They also determined which of the seven specific plastics they were, and charted their shapes—qualities that could be valuable in biomedical research.

Common Plastics Found: PET, PA, PS, PVC and PMMA

One common one was polyethylene terephthalate or PET. This was not surprising, since that is what many water bottles are made of. (It is also used for bottled sodas, sports drinks and products such as ketchup and mayonnaise.) It probably gets into the water as bits slough off when the bottle is squeezed or gets exposed to heat. One recent study suggests that many particles enter the water when you repeatedly open or close the cap, and tiny bits abrade.

However, PET was outnumbered by polyamide, a type of nylon. Ironically, said Beizhan Yan, that probably comes from plastic filters used to supposedly purify the water before it is bottled. Other common plastics the researchers found: polystyrene, polyvinyl chloride and polymethyl methacrylate, all used in various industrial processes.

A somewhat disturbing thought: the seven plastic types the researchers searched for accounted for only about 10% of all the nanoparticles they found in samples; they have no idea what the rest are. If they are all nanoplastics, that means they could number in the tens of millions per liter. But they could be almost anything, “indicating the complicated particle composition inside the seemingly simple water sample,” the authors write. “The common existence of natural organic matter certainly requires prudent distinguishment.”

The researchers are now reaching beyond bottled water. “There is a huge world of nanoplastics to be studied,” said Min. He noted that by mass, nanoplastics comprise far less than microplastics, but “it’s not size that matters. It’s the numbers, because the smaller things are, the more easily they can get inside us.”

To Further Test Tap Water and Snow for Microplastics:

Among other things, the team plans to look at tap water, which also has been shown to contain microplastics, though far less than bottled water. Beizhan Yan is running a project to study microplastics and nanoplastics that end up in wastewater when people do laundry—by his count so far, millions per 10-pound load, coming off synthetic materials that comprise many items. (He and colleagues are designing filters to reduce the pollution from commercial and residential washing machines.) The team will soon identify particles in snow that British collaborators trekking by foot across western Antarctica are currently collecting. They also are collaborating with environmental health experts to measure nanoplastics in various human tissues and examine their developmental and neurologic effects.

“It is not totally unexpected to find so much of this stuff,” said Qian. “The idea is that the smaller things get, the more of them there are.”

The study was coauthored by Xin Gao and Xiaoqi Lang of the Columbia chemistry department; Huipeng Deng and Teodora Maria Bratu of Lamont-Doherty; Qixuan Chen of Columbia’s Mailman School of Public Health; and Phoebe Stapleton of Rutgers University.

Source: Columbia Climate School