Today's KNOWLEDGE Share

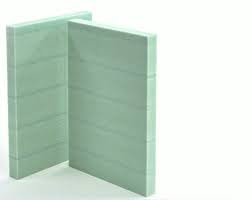

ArmaPET® Struct GRX: next generation in rPET foaming technologyArmacell, a global leader in flexible foam for the equipment insulation market and a leading provider of engineered foams, announces the launch of its latest innovation, the new ArmaPET Struct GRX solution. This cutting-edge development in recycled PET foam core technology delivers significant improvements in sandwich structure production with greater efficiency, cost savings, and sustainability.

Entirely made from recycled plastic bottles, ArmaPET Struct GRX reinforces Armacell’s commitment to sustainability and offers an optimised resin uptake process that drastically improves the weight and cost of sandwich structures. Its remarkable thermal and dimensional stability safeguards high-quality production, while its outstanding fatigue resistance ensures long-term performance and low lifetime maintenance.

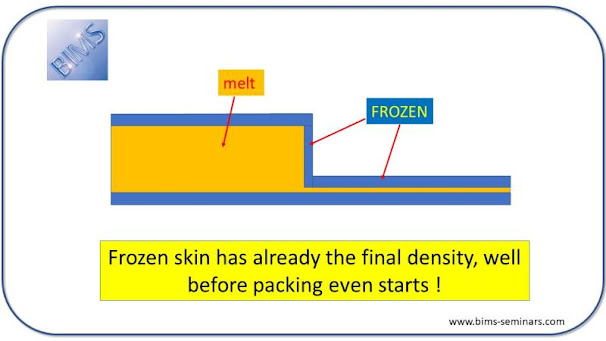

New ArmaPET Struct GRX boasts a more homogenous and finer cell structure compared to previous generations resulting in enhanced shear properties. “We strive for continuous improvement of our product solutions – based on our customers’ needs. ArmaPET Struct GRX provides significant savings in resin uptake to further optimise weight and cost savings.” says Bart Janssen, Armacell’s Vice President Engineered Foams & Energy.

Striving for excellence:

Extensive testing conducted by Armacell proves that ArmaPET Struct GRX exhibits comparable or even superior mechanical performance to its predecessors – for example, its adjusted foam recipe delivers an increase of up to 30 percent in shear properties. This latest product innovation heralds a new era for rPET foaming technology, offering customers unparalleled efficiency gains, cost optimisation, and a sustainable solution.

Source:https://lnkd.in/gyY_h_VS