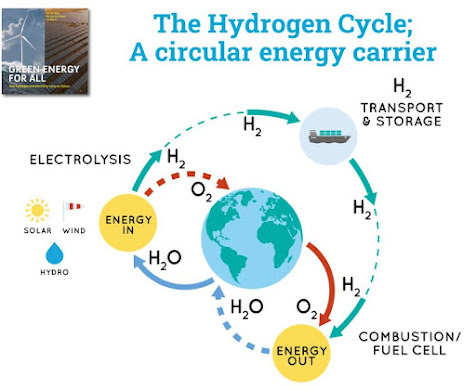

A group of DTU researchers have therefore investigated new possibilities for recycling the plastic waste in collaboration with Roskilde University and a number of industry partners. Their research project RePlastic has shown that a valuable oil can be produced from otherwise useless plastic waste through pyrolysis.

Assessed the Potential of Several Plastic Materials in the Waste:

“I’m surprised at the great potential of pyrolysis technology for the most impure and mixed plastic fractions. This process can handle the plastic we have no other uses for. This enables us to bring end-of-life plastic back into the cycle and make it useful again,” says Anders Egede Daugaard, associate professor at DTU Chemical Engineering and head of the RePlastic project.

To fully understand Anders Egede Daugaard’s enthusiasm, you need to understand the challenges of recycling and sorting plastic waste into different categories and fractions. The current number of different plastic types with different properties is incredibly high—just take a look at your own plastic waste, where you will find hard, soft, ductile, colored, and transparent plastics.

Plastic waste is generally divided into two categories: industrial and household. Industrial plastic waste is usually more uniform as it often consists of only one type of plastic, where both the additives and manufacturing process are known. Household waste, on the other hand, is more often a mixture of different types and grades of plastic. The plastic is then sorted into different fractions depending on properties and quality.

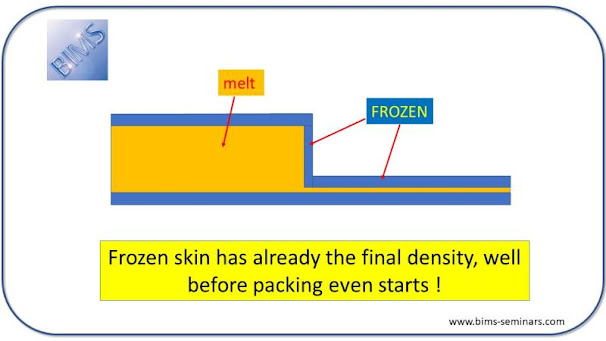

Because the chemical additives vary according to the properties of each plastic product, the plastic waste needs to be sorted before it can be recycled in a mechanical process that granulates, heats, and remolds it into new plastic products. You cannot make new quality plastic from mixed plastic types because the melting point and additives differ and are often completely unknown.

In the RePlastic project, associate professor at DTU Anders Egede Daugaard and his team have assessed the potential of several plastic materials from the least valuable plastic fractions in the #plasticwaste. These fractions are where the majority of the household plastic waste ends up, along with industrial plastic waste that has already been recycled six or seven times and is therefore too worn out to be mechanically recycled again.

#Pyrolysis can Handle the Impurities in the Mixed and Dirty Plastic Waste:

The RePlastic project focused on using pyrolysis for chemical recycling. During the process, plastic waste is heated to high temperatures in a nitrogen-filled furnace, triggering a splitting of the chemical components of the plastic materials. Because there is no oxygen in the furnace, the plastic does not burn, but gasification occurs.

Source: Technical University of Denmark/specialchem

Follow: http://polymerguru.blogspot.com