Supramolecular polymers—the versatile, "next-gen" polymers—offer potential applications in a variety of fields. However, achieving precise control of their polymerization requires a greater understanding of their self-assembly.

Researchers from Chiba University recently studied the impact of different seed/fragment types on polymerization and found that "seed type" influences both the assembly process and the final shape of the structures formed, offering the possibility of developing better and more tailored polymer structures.

Supramolecular Polymers: Reversible and Highly Versatile

Supramolecular polymers are a new class of polymers that are currently being evaluated for material applications. These interesting compounds also play an important role in cellular activities in the body. "Supra," as the name suggests, is attributed to some unique properties that go beyond those of conventional polymers.

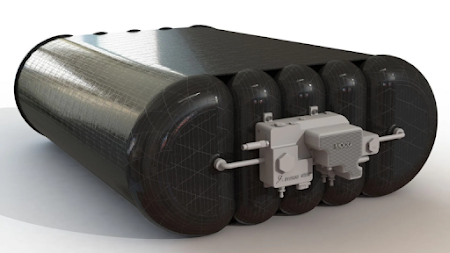

Unlike traditional polymers, which are held together by strong, irreversible covalent bonds, supramolecular polymers are held together by weaker, reversible hydrogen bonds. They can reversibly assemble and disassemble, are highly versatile, and can be used for developing targeted drug delivery therapies, sensors to detect pollutants, diagnostic markers, energy storage devices, personal care products, and self-repairing and recyclable materials. Their excellent recyclability makes them wonderful candidate molecules for sustainable applications; however, there is one roadblock— researchers have yet to understand how to control their polymer growth.

There have, however, been advancements in this aspect. Researchers are now able to build "unlikely" polymers by triggering their assembly with "seeds," enabling control their polymer growth. There are two main mechanisms through which this seed-induced self-assembly occurs: primary nucleation or elongation, where the polymer grows from its end, and secondary nucleation, where new molecules join the polymer by sticking to its surface. The distinction between these processes is important because it enables researchers to better control and manipulate the growth of these unique polymers. Unfortunately, in most cases of seeded self-assembly, primary and secondary nucleation can be difficult to tell apart.

To tackle this issue, a group of researchers led by Professor Shiki Yagai from Chiba University aimed to compare and study the impact of these two processes while delineating the role of precisely controllable "seeded supramolecular polymerization." Their goal was to figure out how different seed shapes affect the formation of new supramolecular polymers; their findings were first published on May 10, 2023, and subsequently appeared in Volume 59, Issue 48 of Chemical Communications on June 18, 2023.

Prof. Yagai tells what motivated the team to pursue this topic of research, "Because of the difficulty in controlling polymerization, supramolecular polymers have not yet reached the point of practical application even though three decades have passed since their establishment as a concept."

He is convinced, however, that because of their versatility, further research in this area is likely to lead to widespread applications of these self-organizing polymers in our daily lives. For their experiments, the researchers used two supramolecular polymers as "seeds." While a closed-ended ring-shaped seed was used in a previous study, an open-ended, helicoidal seed was newly prepared. They found that when the open-ended, helicoidal seed was used, it acted as a template for the target molecules to attach and grow longer. On the other hand, when the closed-ended ring-shaped seed was used, it did not elongate itself, but rather served as a surface where new molecules could attach and form clusters, like a platform for new structures.

Exciting Possibilities for Various Applications

This research shows that the type of seed used in self-assembling supramolecular polymers influences the way the molecules assemble, and the final shape of the formed structures. This opens up exciting possibilities for various applications, from self-repairing and more easily recyclable materials to more advanced drug delivery systems, sensing technologies, and energy storage devices.

As Prof. Yagai states, "By understanding these assembly processes, we can design and develop the next generation of more precise and environmentally friendly polymers with tailored structures and properties. The practical application of supramolecular polymers will enable us to produce plastic materials with lower energy consumption and reduce the energy required for recycling." The ability to manipulate these versatile, self-assembling polymers at the molecular level offers great potential for addressing complex challenges and creating innovative, sustainable solutions in fields ranging from healthcare to environmental sustainability.

Source: Chiba University/SPECIALCHEM

Visit MY BLOG http://polymerguru.blogspot.com

#polymers #supramolecularpolymers #weak #recyclable #seed