Today's KNOWLEDGE Share:

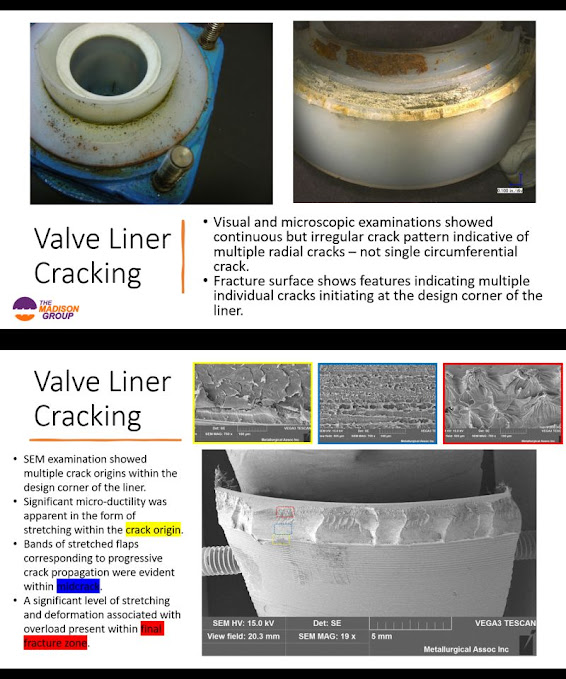

Valve Liner Cracking

I recently wrapped up a failure analysis on a valve liner that had cracked while in service. The valve liner had been machined from perfluoro alkoxy (PFA). In this case, almost no background information was available on the valve application. My client was several steps removed from the installation. This can significantly hamper the failure analysis, limiting the ability to interpret test results.

The visual examination revealed a significant level of rust and adherent gritty debris on the valve liner. A circumferential crack was present within a design corner of the plastic liner. The cracking exhibited a continuous irregular crack pattern indicative of multiple radial cracks, not a circumferential crack. No signs of macro ductility were apparent, and the observed features were characteristic of brittle fracture.

The fracture surface displayed features indicating multiple individual cracks initiating at the liner design corner. The cracking extended radially into the part wall, and the coalescence of the individual cracks formed the circumferential fracture orientation.

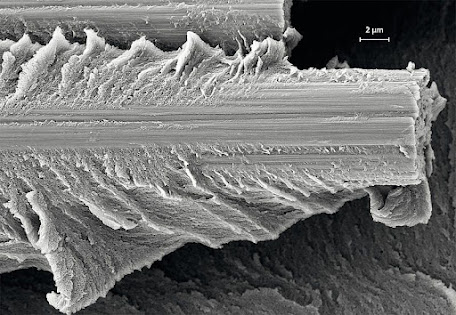

The scanning electron microscopic (SEM) examination confirmed the presence of multiple crack origins, separated by ridgelike features corresponding to crack unions. A significant level of micro ductility was apparent within the crack origins, as indicated by stretched flaps. Striation bands of stretched flaps corresponding to progressive crack propagation were evident extending out from the crack origin area. The features were characteristic of dynamic fatigue. These features extended out from the origin through the mid-crack fracture surface. On the opposite wall of the liner from the crack origins, a significant level of stretching and deformation was apparent. This represented substantial micro ductility, and corresponded to mechanical overload within the final fracture zone.

Overall, the fractographic evaluation indicated that the valve liner failed through dynamic fatigue associated with alternating cycles of cracking and arrest. Based upon the observed striations, it is thought that this was low cycle fatigue, less than 10,000 cycles. However, such assessments can be erroneous, as crack initiation can account for up to 80% of the cycles.

Analytical testing including Fourier transform infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC) produced results characteristic of a PFA resin, with no indication of material irregularities.

Background information detailing the service conditions would have been helpful to identify the source of the stress responsible for the failure, as well as contributing environmental factors.

Source:The Madison Group

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #failureanalysis #cracking #pfa #valves #fractography #sem #dsc