Army soldiers aren’t allowed to use hemp-derived CBD even if it's federally legal—but the military branch is now asking for information about using hemp yarn in uniforms to help camouflage snipers.

In a request for information (RFI) posted last week, the Army said that it’s interested in exploring alternative materials to improve uniforms used by snipers to hide from enemy combatants in close proximity. Hemp and jute are among the materials that it thinks could support the “Operational Clothing and Individual for the Improved Ghillie System (IGS).”

“Interest is specifically in a yarn/twine/thread used to break up the Snipers outline made from Jute, Hemp or similar natural fiber,” the notice says.

The Army’s Product Manager Soldier Clothing and Individual Equipment division is “seeking approximately a 48 lb Jute Count, 3 ply, Jute, Hemp or similar natural fiber, yarn/twine in a natural color,” it continues. “The current demand for the Jute/Hemp yarn is 400,000 yards.”

“The IGS is a new and improved Sniper concealment system developed to meet the concealment needs of the Sniper community. The IGS shall have amendable camouflage materials (e.g. jute, hemp, or similar natural fiber) that can be used to change the appearance of the sniper. The IGS Jute, Hemp, or other natural fiber will help conceal the Sniper and Scout during missions allowing them to remain undetected within close proximity of the enemy forces.”

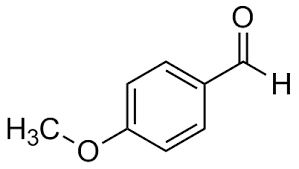

Hemp was federally legalized under the 2018 Farm Bill. And while many have come to associate the crop with its derivatives like CBD oil, there’s growing interest in its other industrial applications, especially given its unique durability, versatility, and low environmental impact. Businesses have been marketing everything from hemp fabric in clothing to hemp concrete for buildings.

Now the Army wants to see whether the crop has the potential to better camouflage its snipers. The RFI says that hemp yarn can be spun domestically or imported from other countries, unlike jute which needs to be spun in the U.S. even if the fiber comes from a foreign source.

“The material shall not present a health hazard to the Soldier and must show compatibility with prolonged, direct skin contact,” it says. Also, the material cannot “add a significant amount of weight” to the uniforms. Responses to the RFI are due by July 27.

House Appropriations Committee has also recently identified the potential of the cannabis crop as a cost-effective alternative to plastics, including language in three recent spending bill reports that encourage research into using domestically grown hemp to reduce dependence on plastic imported from China, for example.

Rep. Dave Joyce (R-OH), a co-chair of the Congressional Cannabis Caucus and member of the Appropriations Committee, is spearheading that initiative.

Source:https://www.marijuanamoment.net/