📢Spreading the Word!📢 Pressurized steam-based composites recycling for full fiber reclamation!

"To date, the most common methods of recycling composite components and materials are pyrolysis (flame-based) or thermolysis (heat-based), solvolysis (chemical-based), hydrolysis (water-based), or some type of mechanical process (chopping or shredding whole parts for reuse, etc.). The end product for most of these processes is a fiber with reduced mechanical properties (the resin having been burned or chemically melted off), suitable for chopping up for potential reuse as a filler, in a nonwoven, mat, or perhaps in injection molding or spray-up applications."

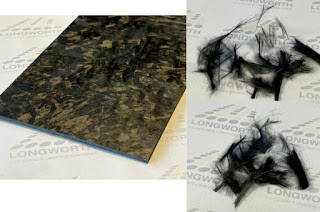

"@Longworth is one company promising a new method for reclaiming both near-virgin-grade fibers and resins. Called DEECOM, the process uses high-temperature steam and pressure to separate and reclaim materials. After a decade of development and proving out the technology, the company is ready to launch DEECOM commercially for composites recycling this year."

"The first iteration of the DEECOM system is set up to process waste in batches. The part to be recycled is fed into the top of a large pressure vessel. Saturated steam is piped into DEECOM’s heating system, superheated to at least 400°C, and then enters the pressure vessel. While the superheated steam is still present, the vessel is pressurized by at least 0.5 bar above atmospheric pressure and goes through several cycles of compression and decompression — the frequency and intensity of the cycles depending on the properties of each material. In practice, each decompression separates more of the resin from the fiber."

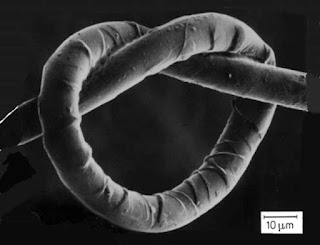

"The resin, now a gas or liquid depending on the type of resin and its reaction to the process, drops down into a collection area, and the fibers are left as intact as they can be, Hill says: “It’s not bent, damaged or burnt, it’s literally just cleaned. It’s in the exact same state as when you put it in, the same length and everything.” The only other waste output is steam expelled via a chimney. This steam can be captured for heat reclamation if required, further reducing the process’ environmental footprint. The timing of the overall process depends on the number of compression/decompression cycles needed for a particular part."

Source: #managingcomposites