Thursday, June 17, 2021

Penn Color Unveils Color Palette for Eye-catching Finish in FMCG Packaging

Creating Building Blocks of Unique Colors

With variations including matte, brushed metal, frost, metallic, luster, and bubbles, penneffex™ offers brands a powerful way to engage with the consumers’ senses and emotions.

Whether the consumer is walking through the store, or idly shopping on-line, penneffex™ enables brand owners and creative marketing teams to better engage with their loyal and new customer base to create a unique and eye-catching product design that conveys brand values like high-end quality, sustainability, transparency, and more. The products utilize creativity and advanced technologies to bring product packaging in line with brand’s messaging and values.

“The core concept of penneffex™ is to create building blocks of unique and differentiated colors and special effects: these building blocks become a source of inspiration for product design teams and they are used in bespoke formulations, developed “live” with our customers, in our technical center.” said Phil Riccardi, industry manager packaging North America. “In a typical 3 day blitz session, we utilize our extensive capabilities and a fast iteration process, to design and prototype 70 to 80 unique concepts, which are presented in their finished part form: with penneffex™, creativity has no boundaries and our development process reduces time to market by months”

The penneffex™ line sets consumer goods products apart from other items on the shelf, by pushing the limits of product packaging design to achieve colors and effects not yet seen on the market today.

Penn Color’s penneffex™ solutions are ideal for unifying brand design across a number of different products, as well as for unique packaging redesigns that are imaginative and product-inspired.

Source: Penn Color

Wednesday, June 16, 2021

Barbara McClintock is the only woman to be awarded an unshared Nobel Prize in Physiology or Medicine.

McClintock discovered 'jumping genes' in corn, and proved that chunks of genetic code can change position on a chromosome, affecting genetic expression.

Born in Hartford Connecticut, McClintock's family had little money, so her interest in research was viewed with skepticism. It was more important for her to marry, her family thought. Despite this, with her father's support, Barbara began studying at Cornell's College of Agriculture in 1919, and her studies are where her interest remained. She was shy and anything but a careerist, but at the same time, she also realized the importance of what she had achieved, not least of all in her role as an example for other women.

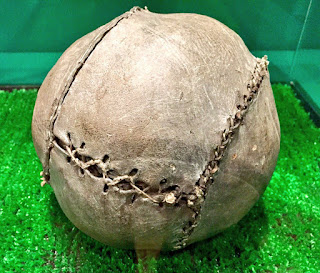

World's oldest football

This is the World's oldest football from 1540. It was made from cowhide with a pig bladder used to inflate the ball. Half the size of a modern football.

The ball was made in Stirling, Scotland, and discovered behind the paneling of the Queen's Chamber in Stirling Castle, which was decorated in the 1540s. Mary Queen of Scots was there at this time and later in life was known to have an interest in all sports but especially golf and football. She recorded a game of football in her diaries while at Carlisle Castle. The ball could have been used in the courtyards within the castle or taken to the royal gardens below the walls. Everyone from the castle, including kings and queens would have been involved. Football was a game for all just as it is today. Was this personal item, belonging to Mary, deliberately placed behind the paneling to act as a protection from witchcraft, a practice common at the time or was it somehow lost. We will never answer that question but we do know that this little ball is the beginning of a sport that now involves a sixth of the population of the world.

Credit: BBC, Peter C. Kjærgaard

Tuesday, June 15, 2021

The photocatalytic system mimics sunflowers by bending towards the light

Scientists have designed a photosensitive hydrogel that can orient towards a light source. The hydrogel mimics phototropism in plants and was used to maximize the energy-harvesting ability of a photocatalyst.

Phototropism allows plants and other organisms to adapt to changing light conditions and maximize energy harvesting throughout the day. Man-made photocatalytic systems, however, typically require direct irradiation from a light source. There are only a few examples of scientists achieving artificial phototropism that are independent of external control and automatically track the direction of light.

Now, a team led by Feili Lai of KU Leuven in Belgium and Tinaxi Liu of Jiangnan University in China has devised a system that combines artificial phototropism with photocatalytic hydrogen peroxide production. Modelled on a sunflower, the system contains two poly(N-isopropyl acrylamide)-based hydrogels. One hydrogel is temperature-sensitive and forms a stem. It also contains reduced graphene oxide (rGO) to absorb light. On top of the stem sits the second hydrogel, which mimics a flower head. It contains a photocatalyst for generating hydrogen peroxide that is made from cadmium sulfide and reduced graphene oxide composite.

When light is shone on the stem, it bends and tracks the light source. This orientates the floral disk towards the light to maximize light absorption so it can maintain a high photocatalytic efficiency regardless of the incidence of light.

The team compared their hydrogen peroxide yield rate to a system without phototropism and saw that while the light-responsive system’s yield remained constant, the yield of the control decreased as the incident angle increased from 0° to 90°.

References

J Qin et al, Energy Environ. Sci., 2021, DOI: 10.1039/d1ee00587a

Saturday, June 12, 2021

Extraordinary new material shows zero heat expansion from 4 to 1,400 K

Australian researchers have created what may be one of the most thermally stable materials ever discovered. This new zero thermal expansion (ZTE) material made of scandium, aluminum, tungsten and oxygen did not change in volume at temperatures ranging from 4 to 1400 Kelvin (-269 to 1126 °C, -452 to 2059 °F).

That's a wider range of temperatures, say scientists from the University of New South Wales (UNSW), than any other material demonstrated to date, and it could make orthorhombic Sc1.5Al0.5W3O12 (catchy name, eh?) a very handy tool for anyone engineering something that needs to work in extremely varied thermal environments.

Examples of where this might come in handy include things like aerospace design, where components are exposed to extreme cold in space and extreme heat at launch or on re-entry. Famously, the SR-71 Blackbird was designed to expand so much at its Mach 3.4 top speed that it would liberally drizzle fuel on the runway at ground temperatures; the fuel tanks wouldn't even fully seal until they heated up. This new material stays exactly the same volume from close to absolute zero all the way up to comfortably over the heat you'd expect to get on the wing of a hypersonic aircraft traveling at Mach 5.

Or there's things like medical implants, where the range of expected temperatures isn't so varied but even a small amount of thermal expansion can cause critical issues.

The UNSW team made the discovery more or less by accident: "We were conducting experiments with these materials in association with our batteries-based research, for unrelated purposes, and fortuitously came across this singular property of this particular composition," says Associate Professor Neeraj Sharma.

After measuring the material using the Echidna high-resolution powder diffractometer at ANSTO's Australian Synchrotron and the Australian Centre for Neutron Scattering, the team found an incredible degree of thermal stability. At the molecular level, materials usually expand because an increase in temperature leads directly to an increase in the length of the atomic bonds between elements. Sometimes it also causes atoms to rotate, resulting in more spacious structures that affect the overall volume.

Not with this stuff, which the team observed across that huge temperature spectrum demonstrating "only minute changes to the bonds, position of oxygen atoms and rotations of the atom arrangements." The team says the exact mechanism behind this extreme thermal stability isn't totally clear, but that perhaps bond lengths, angles and oxygen atom positions are changing in concert with one another to preserve the overall volume."Which part's acting at which temperature, well, that's the next question," says Sharma, who adds, “the scandium is rarer and more costly, but we are experimenting with other elements that might be substituted, and the stability retained,”

The other ingredients, however, are widely available, and bond together using a "relatively simple synthesis," so the team believes this material should present no impediments to large-scale manufacturing.

Source:https://lnkd.in/g-QqTDw

📢Spreading the Word!📢 Williams evolves composites-intensive EV platform!

Williams Advanced Engineering introduced its FW-EVX electric vehicle (EV) platform in 2017, designed to give vehicle manufacturers a modular system with which to develop new vehicles.

''WAE reports that it is applying this innovative modular platform for use in a series of EVs with the top hats engineered for the vehicles by Italdesign, one of the leading transportation design and body engineering companies in the world.''

''The company's approach is, like many EV platforms being developed, skateboard-like in that the rolling chassis is integrated into a flat structure. However, what is different about the Williams solution is that the battery is housed in a molded composite case that is part of the vehicle load structure: front and rear chassis elements are attached to it. Crash loads are transferred through internal reinforcements that are within the side sills.''

To build this structure WAE is using both recycled composite material and aluminum; the company claims that the structure “sets new standards for static and torsional stiffness.”

Source:Managing Composites

Friday, June 11, 2021

REGISTER -LEAN SIX SIGMA GREEN BELT TRAINING & CERTIFICATION

Is Six Sigma still relevant today?

WORKPLACE FLOOR MARKINGS : Simple Lines. Clear Rules. Fewer Incidents.

WORKPLACE FLOOR MARKINGS Simple Lines. Clear Rules. Fewer Incidents. Clear floor markings are a visual management tool that improves safet...

-

Envalior launches new PPS compounding facility in Uerdingen, Germany. New facility supports growing demand for Xytron™ in Europe and the Ame...

-

Today's KNOWLEDGE Share What Is Going Wrong in UK Plastics Recycling? Biffa shut its Sunderland plant. Viridor walked away from Avonmout...

-

Today's KNOWLEDGE Share “Robotic 3D printing can compete with traditional boatbuilding”, Simone Barbera and Mattia De Santis, Caracol V...