Apart from pilots and sea captains, most of us use either the Imperial or the metric system when calculating how far we need to get to where we are going. However, aviation navigation has adopted the ways of its marine counterpart, as it also travels across distances great enough to cross several latitudal lines. Not to mention to save air traffic control a great deal of potential confusion when communicating with international pilots.

One sixtieth of a latitudal degree

As the term ‘nautical’ would imply, the usage is a crossover from seafaring navigation. The NM is based on the circumference of the Earth. For a weekend cruise on a sailboat or a short European domestic hop, the fact that we live on a sphere hurtling through space and wobbling around its own axis is not of great importance. Meanwhile, when traveling long great circle distances, you want to use a unit that is directly related to latitude and longitude.

Historically, one nautical mile was defined as one minute arc of latitude along any line of longitude. One latitude arc is, in turn, divided into 60 minutes, so one NM equals 1/60 of a latitudal degree. However, at the First International Extraordinary Hydrographic Conference in Monaco, in 1929, the international nautical mile was set to exactly 1,852 meters or 1.151 miles.

No set date to phase out non-SI units

In 1947, the International Civil Aviation Organisation (ICAO) adopted a resolution to standardize the unit system across aviation. This introduced the International System of Units, known as SI from the ‘Système International d’Unités’, and was to be based on the metric system.

Meanwhile, the ICAO recognised that shifting measurements too quickly could mean chaos in the skies. And so it said that some non SI-units (such as the nautical mile and the knot) should be kept until the organisation could set a date for their termination. Such a date is yet to be set.

Even though aviation uses NM, you will still see aircraft speed presented in miles or kilometers per hour by their manufactureres. When aircraft changed their speed measurements to knots, manufacturers felt this made their planes seem slower. Knots are measurements on nautical miles per hour – one knot = one NM/h, giving a significantly lower number than miles or kilometers.

Three ways of measuring speed

Meanwhile, the aircraft’s actual speed when flying is measured in knots. Indicated Airspeed (IAS) is read directly from the airspeed indication instruments in the cockpit, connected to a pitot-static system. This measures the dynamic pressure of the air outside entering a pitot-tube.

True Airspeed (TAS), on the other hand, is the plane’s speed in relation to undisturbed air. Meanwhile, Groundspeed is the speed of an aircraft relative to the ground.

However, NM is not the distance measurement in aviation across the board. Cloud clearance is measured in statute miles or KM, and visibility can be measured in miles, or in meters.

What was the first application of carbon fibers? It's not what you are thinking! 👀

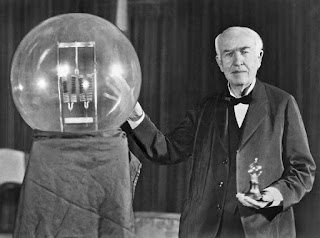

Carbon fibers are older than you imagine! The first carbon fibers date back to 1860! In 1879, a certain guy named Thomas Edison chose carbon fibers to manufacture light bulb filaments. At that time, they were not petroleum-based. Instead, they were produced through the pyrolysis of cotton or bamboo filaments. These filaments were ''baked'' at high temperatures to cause carbonization to take place.

But why were they chosen? The answer is pretty straightforward and has nothing to do with high strength! At the time, Edison noticed that their high heat tolerance made them ideal electrical conductors. However, soon later tungsten took over as the light bulb filament of choice in the early 1900s, and carbon fiber became obsolete for the next 50 years or so.