Paint from cow dung - first-of-its-kind!! Khadi India launched Prakritik emulsion paint which has cow dung as its main ingredient. Cow dung makes for 20-30% of the paint’s ingredients and so it is anti-fungal, non-toxic, anti-bacterial, cost-effective and odorless.

Tuesday, February 23, 2021

Solar powered tent

Solar powered tent - world’s 1st solar heated military tent!! Sonam Wangchuck has come up with an innovation that could help people stay warm in the freezing cold of Ladakh. It can keep them warm at 15 degrees even when it is -14 degrees outside.

It uses only sunlight, water and insulated layers to maintain temperature. The solar heated tents can be used by 10 people at a time and is completely portable. The weight of the tent is less than 30 Kg. Wangchuck is the founder of Student Educational and Cultural Movement in Ladakh.

The whole institute is designed with solar energy and uses no fossil fuel for cooking lighting or heating.This replaces tons of kerosene fuel, pollution and emission.

Thursday, February 18, 2021

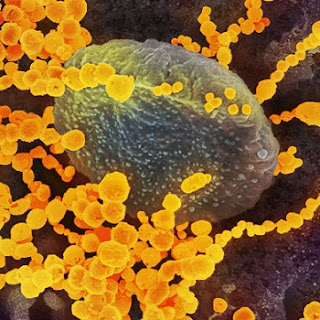

Scientists Find Self-sterilizing Polymers Effective Against Coronaviruses

Researchers from North Carolina State University, Boston University and Kraton Corporation have demonstrated a family of self-sterilizing polymers that are effective at inactivating coronaviruses, including SARS-CoV-2 – the virus that causes COVID-19.

The work opens the door to a suite of applications that could help to reduce the transmission of COVID-19 and other diseases.

Inactivating Viruses on High-contact Surfaces

The work provides conclusive evidence that these anionic polymers, can inactivate human coronaviruses quickly and efficiently.

“If we want to coat high-contact surfaces such as textiles, countertops or walls – it’s possible,” says Frank Scholle, NC State. “Virus inactivation will occur as long as there is sufficient humidity,” adds Scholle.

When these anionic polymers absorb water, protons can travel through nanoscale channels to the surface, creating a highly acidic environment capable of inactivating viruses and killing bacteria and mold. The research team had previously demonstrated that several of the anionic polymers were effective against a range of pathogens, including methicillin-resistant Staphylococcus aureus (MRSA) and a strain of influenza.

“Based on what we’ve learned, we’ve been able to identify a fundamentally new inactivation mechanism and a family of polymers that expands the health care sector’s arsenal for fighting the spread of coronavirus,” Richard Spontak, North Carolina State University, says.

In laboratory experiments, the researchers demonstrated that specific anionic polymers could fully inactivate SARS-CoV-2 in just 5 minutes, and fully inactivate a human coronavirus surrogate called HCoV-229E in 20 minutes.

Evaluating Applications of the Polymers

Kraton Corporation is in the process of evaluating applications for how some of these polymers might be used in a variety of settings.

“We are thankful for the opportunity to collaborate with NC State University and Boston University to address an important and urgent need for long-lasting antimicrobial performance,” says Vijay Mhetar, Kraton’s chief technology officer. “Building upon this scientific discovery, Kraton Corporation is actively seeking regulatory approvals and evaluating application uses in transportation, health care, and building and infrastructure.”

Source: North Carolina State University

Hyundai Motor Group and POSCO form hydrogen partnership

Hyundai Motor Group and POSCO have formed a new hydrogen partnership, through which they will jointly develop hydrogen energy utilisation technologies.

Announcing details of partnership earlier this week (16th Feb), the companies said they will convert POSCO Steelworks’ work vehicles to hydrogen alternatives.

It is thought approximately 1,500 vehicles operated at POSCO Pohang and Gwangyang Works will be converted to Hyundai Motor’s pollution-free hydrogen electric vehicles in stages.

Hyundai Motor Company plans to develop commercial hydrogen trucks in consideration of the characteristics of heavy-duty steel logistics, and POSCO plans to use by-product hydrogen produced in steel mills as the energy source for hydrogen trucks.

The two companies also agreed to cooperate with the construction of a hydrogen charging station for hydrogen trucks in the steel mill.

Source: Hyundai Motor Group

Sunday, February 14, 2021

Blue hydrogen as a bridge to green

Steam methane reformers consume natural gas to make grey hydrogen and they emit carbon dioxide as a consequence. In the long term, that can be mitigated with a transition to ‘green’ hydrogen production using electrolysers which can be fed with renewable electrical power or steam methane reformers fed with renewable biogas.

In the short-term retrofitting carbon capture to steam methane reformers (SMR), autothermal reformers (ATR) and gasification reactors to make so-called ‘blue hydrogen’ will make a big difference. Whether the carbon dioxide is captured and utilized (CCUS), or captured and stored (CCS) in permanent underground storage will in some way depend on the use-cases that are developed and commercialised.

On the 27th of January the European Parliament voted that blue hydrogen produced on SMRs from natural gas with CCS will be an acceptable bridge on the journey to full decarbonisation with green hydrogen. This must be one of the most important hydrogen policy decisions that has been taken recently. Surely this is the green light that is needed to get on with rapid and deep decarbonisation in many carbon-intensive sectors. It means that blue hydrogen will have political and market acceptance. The risk of stranded assets and bad investment decisions has been reduced.

Carbon capture is likely to add some cost. And it simultaneously represents a business opportunity. Much of the carbon dioxide that enters food and beverage value chains for freezing and carbonation applications is captured from ammonia production. Although carbon dioxide production generally far outstrips requirements in those industries.

Increasingly, carbon dioxide is also recovered from refinery SMRs. The advantage of having a carbon dioxide source from a refinery is that production is highly stable through the year because the demand for many fuels is not particularly seasonal. A guaranteed all year-round source of carbon dioxide can put the industrial gases supplier a highly reliable position with significant competitive advantage.

Bulk liquid carbon dioxide from a CCUS scheme can also be converted to dry ice for temperature-controlled supply chains. Dry ice gets daily attention at present for its role in the fight against the Coronavirus. Some vaccines must be shipped and stored at around minus 80 degrees Celsius and dry ice is ideal to maintain this low temperature.

The future of carbon dioxide utilisation will transform in the coming decades as decarbonisation deepens. Synthetic liquid fuels, known as e-fuels is one potential area. They are called e-fuels because electrical power is where the energy to create them comes from. Some electrolyser technologies such as the AEC and PEM can produce high quality hydrogen.

The solid oxide electrolyser can do that too, but it can go one step further. When they are fed with a mixture of steam and carbon dioxide, they can make syngas. And from syngas products such as petrol, diesel and jet fuel can be made using Fischer-Tropsch conversion.

Fischer-Tropsch conversion was used at scale by SASOL in South Africa several decades ago. Today, major GTL or gas to liquid projects such as Bintalu, Onyx, Escavos, Lu’an and Pearl all use the technology to convert syngas (which is produced on gasifiers or auto thermal reformers with the help of super-scale ASUs) to liquid fuels.

To decarbonise that process, the coal or natural gas feedstocks must be switched to steam and carbon dioxide, and the gasification unit or ATR must be replaced with a solid oxide electrolyser. It sounds easy, but the reality is that the change will take time and scale up is never as simple as it sounds. There is still lots of room for innovation from technology experts.

Another pathway to syngas from carbon dioxide is dry reforming of methane. Dry methane reforming uses carbon dioxide to react with the methane instead of steam. As with solid oxide electrolysis, the result is syngas which can be converted to liquid fuels.

Dry methane reforming is related to steam methane reforming, but it is different and more challenging. The process has been known about for decades. The barrier to commercialisation has been the difficulty in finding a catalyst that is able to convince the extremely stubborn carbon dioxide molecule to break apart and join the reaction to produce syngas without that same catalyst getting deactivated by carbon deposits. Innovation in this area will run and run. And it will be worth it.

Using carbon dioxide to make fuel that then burns to release carbon dioxide is an example of the circular economy. And the circular economy is simply nature in action – a man made carbon cycle.

Friday, February 12, 2021

World’s first hydrogen double deckers enter service in Aberdeen

Run by First Bus – Scotland’s largest bus operator – in a project led by Aberdeen City Council, the world’s first fleet of double decker hydrogen buses represent a major step forward in reducing climate change. This launch also underlines the Aberdeen’s role as the energy capital of Europe and shows its commitment to green energy as part of the city’s Net Zero Vision. In addition, plans are in place for Aberdeen to make its own hydrogen to power the buses, making it an even greener energy source for the local community.

The new £8.3million project is part of the European Union’s JIVE grant, which aims to aid commercialization of hydrogen buses through joint procurement between cities and funded by the Fuel Cells and Hydrogen Joint Undertaking (FCH JU). Manufactured by Wrightbus, the vehicles will be operated mainly on the Service 19 (Peterculter to Tillydrone).

“Aberdeen is one of Europe’s pioneering hydrogen cities and through the work of the city council, it has developed a cluster of hydrogen activity and the new double decker buses are a great addition to one of the largest and most varied fleets of hydrogen vehicles in Europe. They have even more advanced technology which pushes established hydrogen boundaries and will greatly assist us in tackling air pollution in the city,” said Aberdeen City Council Co-Leader Councilor Jenny Laing.

The new 60-seat double-deckers, which take less than 10 minutes to fully refuel, are set to transform the air of the city as they save one kilogram of CO2 with each kilometer they drive. The buses will also tackle more than just air pollution, as they are virtually silent helping to create quieter streets. While prototype hydrogen buses were designed and used previously, these double deckers are the first of their kind to go into commercial operation.

Andrew Jarvis, Managing Director at First Bus, said: “Today marks a significant milestone in our industry and the way that people choose to travel. First Bus serves thousands of customers in Aberdeen and we know that so many of our customers take the bus because they care about our planet and reducing their carbon footprint. We’re excited to now be able to offer them an even greener and quieter way of getting about the city.”

Wrightbus chairman, Jo Bamford, also commented: “Everyone at Wrightbus is incredibly proud to see the world’s first hydrogen double decker bus fleet in full service and carrying passengers around the streets of Aberdeen. It marks a pivotal moment in the city’s commitment to reaching net zero. We will see further Wrightbus hydrogen buses in locations across the UK, with fleets due to launch in Birmingham and London later this year. It’s vital that other towns and cities sit up and take note of their example.”

The buses have a bespoke hydrogen fuel system from Luxfer Gas Cylinders. The system for the 15-strong fleet features Luxfer’s G-Stor™ H2 cylinders. “The hydrogen economy is now taking off, but it’s an area we’ve worked in for three decades. Luxfer has pioneered hydrogen storage systems and valve technology, and we were brought into this project by Wrightbus in 2017 to help design how the hydrogen system could work to deliver the best range, in a cost effective solution,” added Mark Lawday, Director of Luxfer Gas Cylinders.

Source: Aberdeen City Council/Luxfer Gas Cylinders

Thursday, February 11, 2021

Kuwait oil giant announces biggest ever gas discovery

Kuwait Foreign Petroleum Exploration Company (KUFPEC) on Wednesday revealed details of its largest ever gas discovery.

According to a release, the company said the discovery, which was made through its wholly owned subsidiary KUFPEC Malaysia (SK-410B) Limited, was proven by the Lang Lebah-2 appraisal well in the SK-410B Block, located approximately 90 kilometres offshore Sarawak, Malaysia.

The appraisal drilling campaign followed the successful drilling of the first exploration well, Lang Lebah-1RDR2, in the SK 410B Block, in 2019.

A statement said: "KUFPEC Malaysia (SK-410B) Limited holds a 42.5 percent working interest under the PSC, with Petronas Carigali Sdn. Bhd. and PTTEP HK Offshore Limited (as operator) holding 15 percent and 42.5 percent working interests, respectively."

It added: "The appraisal drilling in Lang Lebah-2 was completed at a total depth of 4,320 metres, with over 600 metres of proven net gas pay."

The well was tested and flowed at 50 million cubic feet of gas-per-day with a significant amount of gas in place, indicating a substantially larger reservoir than the initial estimate.

"This successful world-class gas discovery is a testament to our steadfast efforts to maximise the value to our shareholder by exploring for hydrocarbons in highly prolific basins," said KUFPEC CEO Shaikh Nawaf Saud Al-Sabah.

"KUFPEC played a strong and active role in maturing the prospect that led to a giant discovery. I am proud of our team," he added.

KUFPEC is an international upstream company engaged in exploration, development and production of crude oil and natural gas outside Kuwait and is a wholly owned subsidiary of Kuwait Petroleum Corporation (KPC).

Source:Arabian Business

Today's KNOWLEDGE Share : Understanding the Critical Difference Between Mold Weight and Clamping Force

Today's KNOWLEDGE Share Understanding the Critical Difference Between Mold Weight and Clamping Force My mold is 5 tons, can it run in a ...

-

Envalior launches new PPS compounding facility in Uerdingen, Germany. New facility supports growing demand for Xytron™ in Europe and the Ame...

-

Today's KNOWLEDGE Share What Is Going Wrong in UK Plastics Recycling? Biffa shut its Sunderland plant. Viridor walked away from Avonmout...

-

Today's KNOWLEDGE Share “Robotic 3D printing can compete with traditional boatbuilding”, Simone Barbera and Mattia De Santis, Caracol V...

The paint can be applied on interior as well as exterior walls. It dries in less than 4 hours, and has a smooth and uniform finish. This paint will instantly reduce the temperature of a room if the outer environment is hot and will maintain the temperature if it is cold outside. It has even successfully tested for radiation prevention. It has been certified by Bureau of Indian Standards. They have priced the distemper paint at Rs 120 per litre and emulsion paint at Rs 225 per litre. Khadi Prakritik Emulsion paint meets BIS 15489:2013 standards whereas Khadi Prakritik Distemper paint meets BIS 428:2013 standards.