'Paired with carbon capture technology, this could lead to an

incredibly green production mechanism for everyday plastics, meanwhile

sequestering harmful greenhouse gases'

Researchers have developed a method for efficiently converting carbon dioxide into plastic.

They say their findings could help divert carbon dioxide – a major contributor to climate change – from entering the atmosphere.

They could also help to reduce our reliance on fossil fuels.

A team of scientists from University of Toronto, University of California, Berkeley and the Canadian Light Source (CLS) successfully managed to work out the ideal conditions for converting carbon dioxide to ethylene.

Ethylene is used to make polyethylene, the most commonly used plastic in the world.

At the heart of the experiment was the carbon dioxide reduction reaction, which can be used to convert the gas into a variety of different substances.

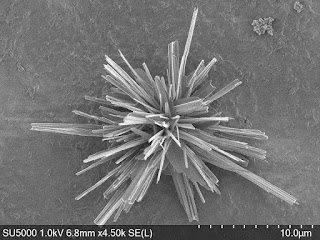

Different metals can be used as a catalyst in this type of reaction, but the researchers chose copper, as its use can lead to the production of ethylene.

“Copper is a bit of a magic metal. It’s magic because it can make many different chemicals, like methane, ethylene, and ethanol, but controlling what it makes is difficult,” said lead researcher Phil De Luna.

The researchers were able to design a catalyst and identify the precise conditions that maximise ethylene production during the reaction, while minimising methane and carbon monoxide production.

“I think the future will be filled with technologies that make value out of waste. It’s exciting because we are working towards developing new and sustainable ways to meet the energy demands of the future,” De Luna added.

The researchers say it is now possible to engineer a catalyst to meet those conditions, and that their findings could have “dramatic” positive effect.

“Paired with carbon capture technology, this could lead to an incredibly green production mechanism for everyday plastics, meanwhile sequestering harmful greenhouse gases.

For detailed article of this,kindly contact me on here with your email.

Researchers have developed a method for efficiently converting carbon dioxide into plastic.

They say their findings could help divert carbon dioxide – a major contributor to climate change – from entering the atmosphere.

They could also help to reduce our reliance on fossil fuels.

A team of scientists from University of Toronto, University of California, Berkeley and the Canadian Light Source (CLS) successfully managed to work out the ideal conditions for converting carbon dioxide to ethylene.

Ethylene is used to make polyethylene, the most commonly used plastic in the world.

At the heart of the experiment was the carbon dioxide reduction reaction, which can be used to convert the gas into a variety of different substances.

Different metals can be used as a catalyst in this type of reaction, but the researchers chose copper, as its use can lead to the production of ethylene.

“Copper is a bit of a magic metal. It’s magic because it can make many different chemicals, like methane, ethylene, and ethanol, but controlling what it makes is difficult,” said lead researcher Phil De Luna.

The researchers were able to design a catalyst and identify the precise conditions that maximise ethylene production during the reaction, while minimising methane and carbon monoxide production.

“I think the future will be filled with technologies that make value out of waste. It’s exciting because we are working towards developing new and sustainable ways to meet the energy demands of the future,” De Luna added.

The researchers say it is now possible to engineer a catalyst to meet those conditions, and that their findings could have “dramatic” positive effect.

“Paired with carbon capture technology, this could lead to an incredibly green production mechanism for everyday plastics, meanwhile sequestering harmful greenhouse gases.

For detailed article of this,kindly contact me on here with your email.