Sunday, November 21, 2010

Scientists Manipulate Plant Metabolism to Produce Potential Precursor to Raw Material for Plastics

Thursday, November 18, 2010

LCA by Toyota Tsusho & Braskem Concludes that Green Polyethylene can Reduce GHG Emission

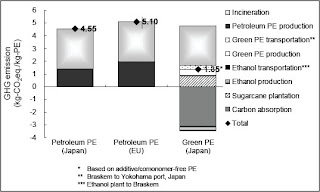

Braskem S.A. and Toyota Tsusho Corporation (Toyota Tsusho) have concluded the joint study of life cycle analysis for polyethylene derived from Brazilian sugarcane (Green Polyethylene), and has found that the Green Polyethylene emits less greenhouse gas (GHG) when compared to petroleum-based polyethylene even if it is delivered to the other side of the earth.

The University of Tokyo, Tokyo, Japan conducted the analysis under the collaborative study with the parties using the preliminary eco-efficiency study performed by Fundação Espaço Eco in Brazil (2007/2008), which shows that 1 kilogram of Green Polyethylene emits 1.35 kilograms* of CO2 equivalents of GHG when it is produced in Brazil, shipped to Japan, used by consumer as container and packaging, and then incinerated. Meanwhile, traditional petroleum-based polyethylene emits 4.55 to 5.10 kilograms in its overall life cycle. As a result, the study demonstrates that 70 to 74 percent of GHG can be reduced with the substitution of Green Polyethylene for traditional polyethylene.

For details of the study, Professor Masahiko Hirao and Assistant Professor Yasunori Kikuchi of the university will deliver a presentation at "International Congress on Sustainability Science and Engineering - ICOSSE11", the most renowned environmental congress held in Tucson, AZ, USA, on January 11, 2011.

Earlier this year, Braskem inaugurated the largest industrial-scale plant of bio-based ethylene with an annual production capacity of 200,000 tons to be converted into the same volume of Green Polyethylene. Toyota Tsusho will start distribution of Green Polyethylene in Asian countries including Japan after certain shipping time from Brazil to the countries.

Wednesday, November 17, 2010

Nobel Laureates from Manchester University Give Graphene a Teflon Makeover

Professor Andre Geim, who along with his colleague Professor Kostya Novoselov won the 2010 Nobel Prize for graphene - the world's thinnest material, has now modified it to make fluorographene - a one-molecule-thick material chemically similar to Teflon.

Fluorographene is fully-fluorinated graphene and is basically a two-dimensional version of Teflon, showing similar properties including chemical inertness and thermal stability. The results have been reported in the advanced online issue of the journal Small. The work is a large international effort and involved research groups from China, the Netherlands, Poland and Russia.

The team hopes that fluorographene, which is a flat, crystal version of Teflon and is mechanically as strong as graphene, could be used as a thinner, lighter version of Teflon, but could also be in electronics, such as for new types of LED devices.

Graphene, a one-atom-thick material that demonstrates a huge range of unusual and unique properties, has been at the centre of attention since groundbreaking research carried out at The University of Manchester six years ago. Its potential is almost endless - from ultrafast transistors just one atom thick to sensors that can detect just a single molecule of a toxic gas and even to replace carbon fibers in high performance materials that are used to build aircraft.

Professor Geim and his team have exploited a new perspective on graphene by considering it as a gigantic molecule that, like any other molecule, can be modified in chemical reactions. Teflon is a fully-fluorinated chain of carbon atoms. These long molecules bound together make the polymer material that is used in a variety of applications including non-sticky cooking pans.

To get fluorographene, the Manchester researchers first obtained graphene as individual crystals and then fluorinated it by using atomic fluorine. To demonstrate that it is possible to obtain fluorographene in industrial quantities, the researchers also fluorinated graphene powder and obtained fluorographene paper.

Fluorographene turned out to be a high-quality insulator which does not react with other chemicals and can sustain high temperatures even in air. One of the most intense directions in graphene research has been to open a gap in graphene's electronic spectrum, that is, to make a semiconductor out of metallic graphene. This should allow many applications in electronics. Fluorographene is found to be a wide gap semiconductor and is optically transparent for visible light, unlike graphene that is a semimetal.

Professor Geim said: "Electronic quality of fluorographene has to be improved before speaking about applications in electronics but other applications are there up for grabs."

Rahul Nair, who led this research for the last two years and is a PhD student working with Professor Geim, added: "Properties of fluorographene are remarkably similar to those of Teflon but this is not a plastic. "It is essentially a perfect one-molecule-thick crystal and, similar to its parent, fluorographene is also mechanically strong. This makes a big difference for possible applications.

"We plan to use fluorographene as an ultra-thin tunnel barrier for development of light-emitting devices and diodes. "More mundane uses can be everywhere Teflon is currently used, as an ultra-thin protective coating, or as a filler for composite materials if one needs to retain the mechanical strength of graphene but avoid any electrical conductivity or optical opacity of a composite".

Industrial scale production of fluorographene is not seen as a problem as it would involve following the same steps as mass production of graphene.

The Manchester researchers believe that the next important step is to make proof-of-concept devices and demonstrate various applications of fluorographene.

Professor Geim added: "There is no point in using it just as a substitute for Teflon. The mix of the incredible properties of graphene and Teflon is so inviting that you do not need to stretch your imagination to think of applications for the two-dimensional Teflon. The challenge is to exploit this uniqueness."

Tuesday, November 16, 2010

First turnkey CNG truck upfitted with vacuum body

Developed in collaboration with Vac-Con, the Freightliner Business Class M2 112V compressed natural gas unit will also be equipped with a CNG-powered auxiliary-mounted engine that powers the truck’s water system. Vac-Con provides combination sewer cleaners to municipal and private markets throughout the world.

Its combination cleaners combine high-pressure water and vacuum systems to effectively clean both sanitary and storm drainage infrastructure. Vac-Con tapped Freightliner Trucks to develop the CNG truck based on its ability to fulfill its unique specs and need for a turnkey chassis solution.

"There’s a tremendous green movement happening now, and our customers are looking to us to provide efficient products with alternative fuel options," said Tom Jody, marketing manager for Vac-Con. "From the beginning, the team at Freightliner Trucks had a genuine interest in this concept, and in its success.

" The truck will include an Allison 3000RDS transmission for optimum performance and efficiency, which include patented torque converter technology that results in improved startability at the launch of the vehicle, full power shifts, and a better performing engine. "The CNG project was truly a partnership and we look forward to continuing our work with Freightliner to further refine this and other natural gas products," Jody added. Freightliner Trucks is a division of Daimler Trucks North America LLC, headquartered in Portland, Oregon.

Tuesday, November 9, 2010

Thermoplastic Robot Suit Makes Aged Body Movement Easy

Carbon-Reinforced Ice Hockey Stick

Toyota Tsusho Signs a Bio-ethanol Offtake Agreement with Petrobras to Produce Bio-PET

Toyota Tsusho Corporation (TTC) recently concluded a long-term bio-ethanol offtake agreement with Petroleo Brasileiro S.A. (Petrobras), Brazilian national oil company.

Brazilian sugarcane ethanol will be used as feedstock in a chemical ethanol project that TTC is deploying with a local partner in Taiwan to produce Bio-PET. TTC agrees to procure sugar cane based bio-ethanol of approximately 1.4 million cubic meters for 10 years from 2012 and the contract is approximately 70 billion yen. This contracted bio-ethanol is supplied to TTC's bio PET business in Taiwan. This agreement will make establish the first global bio-PET integrated supply chain including, procurement of bio-ethanol, production of bio-mono ethylene glycol, tolling business of PET, and marketing of bio-PET.

Petrobras foresees investment in the order of 18 trillion yen in the 2010-2014 business plan. Petrobras has affirmative strategy not only conventional oil and gas projects but also renewable energy including bio-fuel. This long-term offtake agreement is one of the actions to realize their strategy in the bio-fuel business.

This is also first major agreement for Petrobras. And it would establish bio-ethanol supply chain between Brazil and Asia. This agreement will strength partnership with Petrobras. TTC accelerate to expand renewable energy business and continue to strength bio-ethanol supply chain which contributes to lower-carbon society.

WORKPLACE FLOOR MARKINGS : Simple Lines. Clear Rules. Fewer Incidents.

WORKPLACE FLOOR MARKINGS Simple Lines. Clear Rules. Fewer Incidents. Clear floor markings are a visual management tool that improves safet...

-

Envalior launches new PPS compounding facility in Uerdingen, Germany. New facility supports growing demand for Xytron™ in Europe and the Ame...

-

Today's KNOWLEDGE Share What Is Going Wrong in UK Plastics Recycling? Biffa shut its Sunderland plant. Viridor walked away from Avonmout...

-

Today's KNOWLEDGE Share “Robotic 3D printing can compete with traditional boatbuilding”, Simone Barbera and Mattia De Santis, Caracol V...