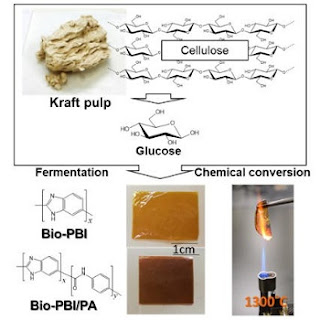

New technology developed at VTT enables the use of pectin-containing agricultural waste, such as citrus peel and sugar beet pulp, as raw material for bio-based PEF-plastics for replacing fossil-based PET. The carbon footprint of plastic bottles can be lowered by 50% when replacing their raw material of PET with PEF polymers, which also provides a better shelf life for food.

Significant Advantage Over Traditional Means

VTT’s technology has significant advantages for making bio-based PEF plastics. The technology uses a stable intermediate to produce FDCA (2,5-furandicarboxylic acid), one of the monomers of PEF, which enables a highly efficient process. In addition, utilizing pectin-containing waste streams opens new possibilities for the circular economy of plastics.

VTT’s unique scale-up infrastructure from laboratory to pilot scale ensures that this new technology will be brought to a technology readiness level that will allow polymer manufacturers’ easy transition to full scale.

Replacing PET in Food Packaging

PET (polyethylene terephthalate) and other polyesters are being widely used in food packaging, plastic bottles and textiles. Replacing fossil-based PET with plant-based PEF (polyethylene furanoate) polymers can lower the carbon footprint of the products by 50%.

“In the near future, you may buy orange juice in bottles that are made from orange peel. VTT’s novel technology provides a circular approach to using food waste streams for high-performance food packaging material, and at the same time reducing greenhouse gas emissions,” shares Professor of Practice Holger Pöhler from VTT.

Moreover, the barrier properties of PEF plastics are better than PETs, meaning that the food products have a longer shelf life. PEF is a fully recyclable and renewable high-performance plastic. Therefore, it opens up possibilities for the industries to reduce waste and to have positive impact on the environment.

Source: VTT