OrganoClick has, by using its innovative fiber modification technology and production process, developed a 100 %bio-based, recyclable and fully biodegradable biocomposite material, OrganoComp®. The biocomposite is made of 3D-moulded biofibers, wheat bran, and food waste.

3D-molded Biocomposite Made of Wheat Bran and Biofibers

Fredahl Rydéns, the Nordics largest supplier of funeral products launches the burial coffin Saga made of OrganoComp®. The strength of the biocomposite enables a 50 %reduction of raw material, reducing the weight from 40 to 20 kg compared with a traditional coffin.

Replace Hard Plastics

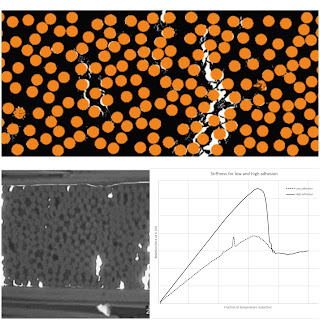

The launch of the burial coffin Saga marks the next step in a journey that started 10 years ago when the development of OrganoComp® was initiated. By using OrganoClick’s patented technology for modification of biofibers, a unique biocomposite has been developed, based on modified cellulose fibers, wheat bran, and biopolymers from food waste such as orange peels and shrimp shells. With OrganoClick’s fiber modification technology, properties such as fire resistance, strength and water repellency can also be added to the material. The biocomposite can be used to replace hard plastics such as polypropylene, or particle boards which contains large amounts of synthetic glue.

New Production Technology for 3D-Molding

In order to make large objects such as coffins, a new production technology for 3D-molding of large fiber-based products, has also been developed, inspired by the production process for molded pulp, used for e.g. packaging. This has resulted in a highly automated production of large, complex, 3Dshaped products. The coffin Saga is with this technology, produced in only two pieces (lid and bottom), before being assembled to a final coffin.

OrganoComp® - Replacing Polypropylene

OrganoComp® has now been implemented in two industrial applications. In addition to the burial coffin Saga, a sound absorbing acoustic panel has been launched by Baux, a leading supplier of acoustic products. New applications in the pipeline include a risk waste container used in hospitals, where OrganoComp® is replacing polypropylene. Other future applications of OrganoComp® include furniture, interior design and specialty packages.

“OrganoClick’s biocomposites are based on research within biomimicry from Stockholm University and the Swedish University of Agricultural Sciences. By mimicking nature’s own chemistry, and combine this with our unique fiber molding technology, we have developed strong and durable materials which can be used in such demanding products as burial coffins with high requirements on quality and surface smoothness”, says Mårten

Serial production will now start of the burial coffin Saga and the acoustic panel in OrganoClick’s factory north of Stockholm. The first production line has a capacity of producing 50,000 burial coffins / year.

Source: OrganoClick