Monday, December 31, 2018

Sunday, December 30, 2018

An eco-friendly vinyl hybrid resin made with zero styrene

Perma-Liner

Industries, the manufacturer and supplier of trenchless pipeline

rehabilitation equipment and materials in North America, is introducing a

eco-friendly resin called Perma-Liner vinyl hybrid resin.

“Our newest resin, the Vinyl Hybrid, has an array of benefits that are attractive to those looking for reduced labor costs, fast cure times and more,” said Rishi Vasudeva, business excellence manager at Perma-Liner. “This Resin is formulated with zero styrene – a potentially harmful substance per OSHA – allows it to be used in areas that would previously need to be evacuated due to the presence of styrene, such as schools, hospitals, churches, office buildings and more.”

The

vinyl Hybrid resin has a standard pot life of more than eight hours and

uses an easy initiator with one percent cumyl hydroperoxide (CHP) by

weight making it cheap, easy and effective. With this new resin, it can

be hot water or steam cured at a minimum of 140°F temperature held for

28 minutes with no post cure. The lower cure temperature of 140°F means

it’s safer, gentler on equipment, a short time to maintain the

temperature and easier temperature to reach for longer shots.

Perma-Liner’s vinyl hybrid boasts consistent viscosity and is resistant

to sag and draining around vertical surfaces and reinforcement.

Perma-Liner’s

newest resin joins the company’s other resins: the high-performance

vinyl ester, styrene-free silicate and the ever-popular 100 percent

solids epoxy.

Source:perma-liner

Tuesday, December 25, 2018

Scientists Discover Method to Produce FDCA Using Non-food Glucose Derivative

Scientists have discovered a novel method to synthesize

furan-2,5-dicarboxylic acid (FDCA) in a high yield from a glucose

derivative of non-food plant cellulose, paving the way for replacing

petroleum-derived terephthalic acid with biomaterials in plastic bottle

applications.

The chemical industry is under pressure to establish energy-efficient

chemical procedures that do not generate by-products, and using

renewable resources wherever possible. Scientists believe that if

resources from non-food plants can be used without putting a burden on

the environment, it will help sustain existing social systems.

In the study published in Angewandte Chemie International Edition, a Japan-Netherland research team led by Associate Professor Kiyotaka Nakajima at Hokkaido University and Professor Emiel J.M. Hensen at Eindhove University of Technology succeeded in suppressing the side reactions and producing FDCA with high yields from concentrated HMF solutions (10~20 wt%) without by-products formation. Specifically, they first acetalized HMF with 1,3-propanediol to protect by-product-inducing formyl groups and then oxidized HMF-acetal with a supported Au catalyst.

Conventional methods produce by-products making large-scale FDCA production difficult, while this new method yields FDCA efficiently without by-products formation.

About 80% of 1,3-propanediol used to protect formyl groups can be reused for the subsequent reactions. In addition, drastic improvement in the substrate concentration reduces the amount of solvents used in the production process.

Kiyotaka Nakajima says “It is significant that our method can reduce the total energy consumption required for complex work-up processes to isolate the reaction product.”

“These results represent a significant advance over the current state of the art, overcoming an inherent limitation of the oxidation of HMF to an important monomer for biopolymer production. Controlling the reactivity of formyl group could open the door for the production of commodity chemicals from sugar-based biomaterials,” says Kiyotaka Nakajima. This study was conducted jointly with Mitsubishi Chemical Corporation.

Source: Hokkaido University

Decreasing Burden on the Environment with Renewable Resources

The chemical industry is under pressure to establish energy-efficient

chemical procedures that do not generate by-products, and using

renewable resources wherever possible. Scientists believe that if

resources from non-food plants can be used without putting a burden on

the environment, it will help sustain existing social systems.

It has been reported that various useful polymers can be synthesized

from 5-(hydroxymethyl)furfural (HMF), the biomaterial used in this

study. A high yield of FDCA can be obtained when HMF is oxidized in a

diluted solution under 2 weight percentage (wt%) with various supported

metal catalysts.

However, a major stumbling block to industrial application lies with the

use of a concentrated solution of 10-20 wt%, which is essential for

efficient and scalable production of FDCA in the chemical industry. When

HMF was simply oxidized in a concentrated solution (10 wt%), the FDCA

yield was only around 30%, and a large amount of solid by-products was

formed simultaneously. This is due to complex side reactions induced

from HMF itself.

Producing FDCA with High Yields

In the study published in Angewandte Chemie International Edition, a Japan-Netherland research team led by Associate Professor Kiyotaka Nakajima at Hokkaido University and Professor Emiel J.M. Hensen at Eindhove University of Technology succeeded in suppressing the side reactions and producing FDCA with high yields from concentrated HMF solutions (10~20 wt%) without by-products formation. Specifically, they first acetalized HMF with 1,3-propanediol to protect by-product-inducing formyl groups and then oxidized HMF-acetal with a supported Au catalyst.

Conventional methods produce by-products making large-scale FDCA production difficult, while this new method yields FDCA efficiently without by-products formation.

Producing Chemicals from Sugar-based Biomaterials

About 80% of 1,3-propanediol used to protect formyl groups can be reused for the subsequent reactions. In addition, drastic improvement in the substrate concentration reduces the amount of solvents used in the production process.

Kiyotaka Nakajima says “It is significant that our method can reduce the total energy consumption required for complex work-up processes to isolate the reaction product.”

“These results represent a significant advance over the current state of the art, overcoming an inherent limitation of the oxidation of HMF to an important monomer for biopolymer production. Controlling the reactivity of formyl group could open the door for the production of commodity chemicals from sugar-based biomaterials,” says Kiyotaka Nakajima. This study was conducted jointly with Mitsubishi Chemical Corporation.

Source: Hokkaido University

Tuesday, December 18, 2018

U.S. DOT approves high-pressure vessel hydrogen transport systems

Hexagon Composites has received a special permit from the United

States Department of Transportation (DOT) for the highest pressure gas

transport systems ever. The permit authorizes the manufacture, marking,

sale and use of Hexagon’s 500 and 950 bar cylinders for over-the-road

transport modules in the United States, for hydrogen and other gases.

“The DOT permit is a milestone for the hydrogen refueling market where higher pressures are sought to move more hydrogen per trailer trip, which in turn reduces the overall price of hydrogen fuel at the pump,” said Hartmut Fehrenbach, Vice President of Hydrogen Distribution of Hexagon. “This represents a key step to accelerate the ongoing adoption of fuel cell vehicles and transformation to a zero-emission and domestically sourced energy landscape.”

Hexagon is the first manufacturer to receive U.S. DOT special permit (SP20391) for 950 bar (13,775 psig). Being able to move 950 bar pressure vessel systems over the road enables the implementation of mobile hydrogen refueling units for fuel cell vehicles using 700 bar on-board storage tanks. Mobile refueling units strengthen the expanding hydrogen refueling network before permanent stations can be established.

Hexagon is designing transport systems for hydrogen for the United States, building on their experience and success with hydrogen transport modules already in use with European distribution customers and Mobile Pipeline® transportation modules in use globally with natural gas distribution customers.

Source: Hexagon

“The DOT permit is a milestone for the hydrogen refueling market where higher pressures are sought to move more hydrogen per trailer trip, which in turn reduces the overall price of hydrogen fuel at the pump,” said Hartmut Fehrenbach, Vice President of Hydrogen Distribution of Hexagon. “This represents a key step to accelerate the ongoing adoption of fuel cell vehicles and transformation to a zero-emission and domestically sourced energy landscape.”

Hexagon is the first manufacturer to receive U.S. DOT special permit (SP20391) for 950 bar (13,775 psig). Being able to move 950 bar pressure vessel systems over the road enables the implementation of mobile hydrogen refueling units for fuel cell vehicles using 700 bar on-board storage tanks. Mobile refueling units strengthen the expanding hydrogen refueling network before permanent stations can be established.

Hexagon is designing transport systems for hydrogen for the United States, building on their experience and success with hydrogen transport modules already in use with European distribution customers and Mobile Pipeline® transportation modules in use globally with natural gas distribution customers.

Source: Hexagon

Evonik Offers Methacrylate Monomer with Flame Retardant & Anti-corrosive Properties

Evonik has planned to market 2-hydroxyethyl methacrylate phosphate as an anti-corrosion agent and flame retardant under the brand name VISIOMER® HEMA-P 70M. Typical product applications of this methacrylate monomer include adhesives and plastics, paints and coatings, fibers, composite resins, and gel coats.

New Options Open for Customers with VISIOMER

Customers mainly use VISIOMER® HEMA-P 70M as an adhesion promoter, but the latest findings have also shown it to be an effective halogen-free, reactive flame retardant or anti-corrosion agent.

Since the substance serves as a reactive diluent or as a co-monomer bonded within the polymer backbone, it does not migrate like conventional flame retardants. VISIOMER® HEMA-P 70M further improves flame retardancy in combination with non-polymerizable flame retardants.

“VISIOMER® HEMA-P 70M offers new options for customers with special requirements for flame-retardant and anti-corrosion properties. This monomer adds a specialty methacrylate with particular functionalities to Evonik’s portfolio and underscores our role as a solution provider for innovative customers,” says Dr. Martin Trocha, the head of Evonik’s Application Monomers Product Line.

VISIOMER® HEMA-P 70M is a highly versatile monomer that contains 30% methyl methacrylate and is particularly easy to process because of its low viscosity. Thanks to

its low color index, the specialty monomer is particularly well-suited for optical applications in acrylate and methacrylate systems. This enables the use in applications with high demands for transparency and surface quality, such as surface coatings, plastics or adhesives.

Moreover, the monomer protects against static charging and has an emulsion stabilizing effect.

Source: Evonik

Since the substance serves as a reactive diluent or as a co-monomer bonded within the polymer backbone, it does not migrate like conventional flame retardants. VISIOMER® HEMA-P 70M further improves flame retardancy in combination with non-polymerizable flame retardants.

“VISIOMER® HEMA-P 70M offers new options for customers with special requirements for flame-retardant and anti-corrosion properties. This monomer adds a specialty methacrylate with particular functionalities to Evonik’s portfolio and underscores our role as a solution provider for innovative customers,” says Dr. Martin Trocha, the head of Evonik’s Application Monomers Product Line.

Ease of Process with Low Viscosity

VISIOMER® HEMA-P 70M is a highly versatile monomer that contains 30% methyl methacrylate and is particularly easy to process because of its low viscosity. Thanks to

its low color index, the specialty monomer is particularly well-suited for optical applications in acrylate and methacrylate systems. This enables the use in applications with high demands for transparency and surface quality, such as surface coatings, plastics or adhesives.

Moreover, the monomer protects against static charging and has an emulsion stabilizing effect.

Source: Evonik

Sunday, December 16, 2018

Circa Receives ECHA Approval for Bio-based Di-polar Solvent Manufacture

Circa Group has received authorization from the European Chemicals

Agency (ECHA) to manufacture or import up to 100 tones/year of its

bio-based solvent Cyrene™ in the European Union, after receiving REACH

Annex VIII approval.

A chiral dipolar aprotic solvent, Cyrene™ was developed in conjunction

with the Green Chemistry Centre of Excellence (GCCE) at the University

of York. Cyrene™ is a two-step conversion of waste biomass, produced at

Circa's large-scale prototype plant, built in partnership with pulp and

paper company Norske Skog in Tasmania, Australia.

Solvent regulation is increasingly focused on restricting hazardous chemicals to manage their risk to people animals and the environment. In the EU, widely used solvents such as NMP, DMF and DMAc are on the candidate list of Substances of Very High Concern (SVHC) due to their reprotoxicity.

In addition, a new restriction on NMP was adopted earlier this year, meaning that after May 2020, use will be further restricted and it will not be able to be manufactured or used in the EU unless operational conditions are maintained to ensure that exposure to workers is below specified levels.

Tony Duncan, CEO and co-founder of Circa Group, said, "Annex VIII authorization is a major milestone for Cyrene™ and we are delighted to have been given the go-ahead to sell Cyrene™ in significantly larger quantities in Europe.

Safer solvents are urgently required and with Cyrene™, we are also offering a bio-based solution with a unique property set, including viscosity, surface tension and polarities – making it an exciting new prospect for advanced materials. Our next goal is registration of Cyrene™ in the US and other jurisdictions will soon follow.”

Source: Circa

Cyrene™ : An Alternative to Polar Aprotic Solvents

A chiral dipolar aprotic solvent, Cyrene™ was developed in conjunction

with the Green Chemistry Centre of Excellence (GCCE) at the University

of York. Cyrene™ is a two-step conversion of waste biomass, produced at

Circa's large-scale prototype plant, built in partnership with pulp and

paper company Norske Skog in Tasmania, Australia.

Cyrene™ provides a safer alternative to these polar aprotic solvents

facing regulatory pressure worldwide and is available through Circa’s

distributors Merck/Sigma and Will&Co.

Restricting the Possible Toxic Solvents

Solvent regulation is increasingly focused on restricting hazardous chemicals to manage their risk to people animals and the environment. In the EU, widely used solvents such as NMP, DMF and DMAc are on the candidate list of Substances of Very High Concern (SVHC) due to their reprotoxicity.

In addition, a new restriction on NMP was adopted earlier this year, meaning that after May 2020, use will be further restricted and it will not be able to be manufactured or used in the EU unless operational conditions are maintained to ensure that exposure to workers is below specified levels.

Crossing a Major Milestone

Tony Duncan, CEO and co-founder of Circa Group, said, "Annex VIII authorization is a major milestone for Cyrene™ and we are delighted to have been given the go-ahead to sell Cyrene™ in significantly larger quantities in Europe.

Safer solvents are urgently required and with Cyrene™, we are also offering a bio-based solution with a unique property set, including viscosity, surface tension and polarities – making it an exciting new prospect for advanced materials. Our next goal is registration of Cyrene™ in the US and other jurisdictions will soon follow.”

Source: Circa

Tuesday, December 11, 2018

Sulzer Enters into Partnership to Promote PLA-based Sustainable Plastics Production

Futerro, Sulzer and TechnipFMC team up to simplify the manufacture of bioplastics.

Three major process technology and equipment specialists, Futerro,

Sulzer and TechnipFMC, have formed the PLAnet™ initiative in equal

partnership to promote the production of sustainable plastics made of Poly-Lactic Acid (PLA).

The strategic collaboration will support manufacturers interested in

entering the bioplastic market by delivering integrated PLA technology

packages.

PLA is a versatile bio-based and biodegradable polymer that can replace petroleum-based plastics in a wide range of applications. Different stages are required to convert sugars from crops into lactic acid, lactide and subsequently PLA.

The agreement between the three parties offers to agricultural, chemical

and fiber industries, a fully integrated package addressing the whole

PLA value chain. In this way, customers can benefit from direct access

to state-of-the-art, customizable solutions for all the aspects and

stages of PLA production. PLAnet™ offers the possibility of a “one-stop

shop” for customers interested in PLA production by providing a single

point of contact and responsibility.

In particular, PLAnet™ supports the construction of plants of any size, including PLA facilities with a throughput of up to 100’000 tons per year - that permit manufacturers to save both capital expenditures (CAPEX) and operating expenses (OPEX) by providing for integrated and optimized plant section design.

Within the PLAnet™ partnership, Futerro’s proprietary technology focuses on the production of lactic acid and raw lactide from sugar or, directly, from biomass; Sulzer contributes the process for the purification of lactide and its polymerization to obtain PLA while TechnipFMC acts as technology integrator to deliver seamless and optimized Front-End Engineering Design (FEED) packages.

The promotion of greener alternatives to traditional plastics needs to be backed by suitable technologies that enable the industry to produce high-quality bioplastics in an efficient manner. This can be made possible via the PLAnet™ partnership between Futerro, Sulzer and TechnipFMC by leveraging their world-leading technologies, expertise and skills for the entire PLA value chain.

Source: Sulzer

PLA is a versatile bio-based and biodegradable polymer that can replace petroleum-based plastics in a wide range of applications. Different stages are required to convert sugars from crops into lactic acid, lactide and subsequently PLA.

Facilitating Bioplastics Production

Futerro, a well-established technology provider for lactic acid and lactide production, and Sulzer Chemtech, a leading specialist in separation and mixing technologies have over 25 years of experience in lactic acid and PLA’s related processes. Together they have further shown their commitment to facilitate the production of bioplastics by establishing a partnership with TechnipFMC, a leading global EPC contractor with experience in technology development and licensing with fast growing activities in bioplastics and green chemicals.PLAnet™ Initiative

The agreement between the three parties offers to agricultural, chemical

and fiber industries, a fully integrated package addressing the whole

PLA value chain. In this way, customers can benefit from direct access

to state-of-the-art, customizable solutions for all the aspects and

stages of PLA production. PLAnet™ offers the possibility of a “one-stop

shop” for customers interested in PLA production by providing a single

point of contact and responsibility.

Goal of PLAnet™

In particular, PLAnet™ supports the construction of plants of any size, including PLA facilities with a throughput of up to 100’000 tons per year - that permit manufacturers to save both capital expenditures (CAPEX) and operating expenses (OPEX) by providing for integrated and optimized plant section design.

Within the PLAnet™ partnership, Futerro’s proprietary technology focuses on the production of lactic acid and raw lactide from sugar or, directly, from biomass; Sulzer contributes the process for the purification of lactide and its polymerization to obtain PLA while TechnipFMC acts as technology integrator to deliver seamless and optimized Front-End Engineering Design (FEED) packages.

The promotion of greener alternatives to traditional plastics needs to be backed by suitable technologies that enable the industry to produce high-quality bioplastics in an efficient manner. This can be made possible via the PLAnet™ partnership between Futerro, Sulzer and TechnipFMC by leveraging their world-leading technologies, expertise and skills for the entire PLA value chain.

Source: Sulzer

Saturday, December 8, 2018

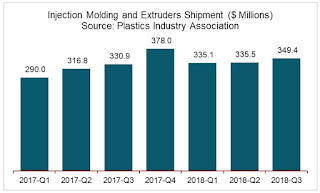

Plastics Machinery Shipments Continued to Increase in Q3 of 2018 in North America

The plastics machinery shipments in North America continued to increase in the third quarter according to the statistics compiled and reported by the Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES).

Injection Molding & Extrusion Machinery Shipment

The preliminary estimate of shipments of primary plastics equipment (injection molding and extrusion) for reporting companies totaled $349.4 million in the third quarter. This was a 4.1-percent increase from the $335.5 million (revised) second-quarter shipment. Injection molding shipments in the second quarter were higher than previously thought. Year over year, shipments grew 5.6 percent.

Perc Pineda PhD, Chief Economist of PLASTICS, said:

“Plastics machinery shipments recovered in the third quarter following a weak second quarter. We expect higher shipments in the fourth quarter. We have a tight labor market and U.S. manufacturers, including plastics machinery manufacturers, have been working on production backlogs. As a result, shipments are pushed into the next quarters.”

Quarterly Statistics

- On a quarterly basis, injection molding shipments increased 2.1 percent. Single-screw and twin-screw extruder shipments continued double-digit growth of 23.8 percent and 14.2 percent, respectively.

- Compared to the third quarter last year, shipments of injection molding were up 4.6 percent. Shipments of single-screw extruders rose 7.7 percent and twin-screw extruders 17.2 percent over the same period.

Perc Pineda said:

“Except for soft auto and home sales numbers in the third quarter, the U.S. economy is still in expansionary mode—and that’s good news for plastics machinery manufacturing. While there are projections of moderate growth next year, it is expected that the U.S. economy will remain healthy.”

Source: Plastics Industry Association (PLASTICS)

Friday, December 7, 2018

California Bans Sale of Upholstered Products Containing FRs Above 1000ppm

California has joined states to ban flame retardants in certain

household products. Starting January 1, 2020, it will be prohibited to

sell or distribute children’s products, mattresses, and upholstered

furniture that contain flame retardants in concentrations above 1,000

parts per million (ppm) in the state of California.

In passing the bill, the Legislature cited proof that flame retardants

do little to increase fire safety, and expressed concerns about the link

between flame retardants and various health problems, such as

developmental problems in children and cancer.

The Bureau of Electronic and Appliance Repair, Home Furnishings, and Thermal Insulation is sanctioned to enforce the new law and adopt implementing rules and regulations.

California is one of a number of states that have banned flame retardants or specific chemicals commonly used in FRs.

Source: SpecialChem

Link Between Flame Retardants and Various Health Problems

In passing the bill, the Legislature cited proof that flame retardants

do little to increase fire safety, and expressed concerns about the link

between flame retardants and various health problems, such as

developmental problems in children and cancer.

Implementing Rules and Regulations

The law needs the International Sleep Products Association to survey mattress producers every three years to determine what materials are being used to meet flammability standards.The Bureau of Electronic and Appliance Repair, Home Furnishings, and Thermal Insulation is sanctioned to enforce the new law and adopt implementing rules and regulations.

California is one of a number of states that have banned flame retardants or specific chemicals commonly used in FRs.

San Francisco’s Flame Retardant Ban to Take Effect

- On January 1, 2019, San Francisco’s similar ban on sale of upholstered furniture and juvenile products containing flame retardants goes into effect

- From next year, it will be prohibited to sell upholstered furniture, reupholstered furniture, or juvenile products which have been made with, or contain a flame retardant chemical at a level above 1, 000 parts per million.

- The same ban goes into effect on July 1, 2019 for similar products that have electrical or electronic components.

Labeling Requirements

- In addition to banning the sale of products with added flame retardants, the San Francisco ordinance includes labeling requirements for all upholstered furniture and children’s products sold in the city.

- The products must be affixed with labels that state that the item does not contain the flame retardants.

- The labels required by San Francisco’s ordinance are the same as those currently required under California’s SB 1019, but the label must be marked to indicate that the upholstery materials contain NO added flame retardant chemicals.

Penalties for Violation

Penalties for violation of the ordinance may not exceed $1,000 per day per violation, with each day constituting a separate violation, and each product for sale also constituting a separate violation. In determining the appropriate penalty, the Director or the court will consider “the extent of harm caused by the violation, the nature and persistence of the violation, the frequency of past violations, any action taken to mitigate the violation, and the financial burden to the violator.”Source: SpecialChem

Wednesday, December 5, 2018

Teknor Apex’s New Medical-grade TPEs Replace Silicone in Biopharmaceutical Tubing

Three new medical-grade thermoplastic elastomers (TPEs) for

biopharmaceutical tubing provide performance superior to the industry

standard TPE in this application, making them effective alternatives to

widely used silicone.

Teknor Apex Company will introduce the new Medalist® compounds at MD&M West (Booth 2015) and will make a presentation on grades for peristaltic pump applications at the “Tech Theater” during the show. The presentation is scheduled for 1:30 pm on Wednesday, February 6.

Teknor Apex recommends three compounds for challenging tubing applications in the biopharma industry for peristaltic pumps and extreme low temperature applications. The materials designed for peristaltic pump tubing provide the elasticity required to keep pace with rapid pump action and the durability needed for the tubing to retain its shape and remain intact over time. In comparison with the industry-standard TPE alternative to silicone, the Medalist TPEs exhibit lower levels of spallation—the shedding of particles from the inner and outer surfaces of the tubing caused by repeated compression and release during pump operation.

• Medalist MD-12352 is a 52 Shore A translucent TPE designed for peristaltic pump tubing.

The new Medalist compounds are made with FDA-listed ingredients, are certified at a minimum to the ISO 10993-5 standard for biocompatibility, and are REACH SVHC compliant. They are free of DEHP and other phthalates, BPA, and latex. Standard grades are ADM-free.

Source: Teknor Apex Company

Teknor Apex Company will introduce the new Medalist® compounds at MD&M West (Booth 2015) and will make a presentation on grades for peristaltic pump applications at the “Tech Theater” during the show. The presentation is scheduled for 1:30 pm on Wednesday, February 6.

Clear & Translucent Medalist® Medical TPEs

Teknor Apex recommends three compounds for challenging tubing applications in the biopharma industry for peristaltic pumps and extreme low temperature applications. The materials designed for peristaltic pump tubing provide the elasticity required to keep pace with rapid pump action and the durability needed for the tubing to retain its shape and remain intact over time. In comparison with the industry-standard TPE alternative to silicone, the Medalist TPEs exhibit lower levels of spallation—the shedding of particles from the inner and outer surfaces of the tubing caused by repeated compression and release during pump operation.

Three New Medalist® Compounds

• Medalist MD-12352 is a 52 Shore A translucent TPE designed for peristaltic pump tubing.

• Medalist MD-50357 is a clear, slightly harder TPE (58 Shore A) for peristaltic pump tubing, which can be sterile welded and heat sealed.

• Medalist MD-10353

is a clear compound used in biopharma tubing in extreme low temperature

applications. With a brittleness temperature below -60° C, this TPE can

be used for tubing that remains flexible and elastic, facilitating

fluid transfer in the manufacturing process of heat-sensitive

biopharmaceuticals.

These three Medalist compounds exhibit significantly lower permeability

than silicones. They can be sterilized by means of e-beam, gamma

irradiation, and ethylene oxide (EtO).

Ross van Royen, senior market manager of regulated products, said:

“At a time when silicones are in short supply, Teknor Apex can

provide an assured global supply chain for all Medalist TPEs, producing

them at ISO-13485-certified facilities in the U.S, and Singapore. As

alternatives to silicone, our three new Medalist compounds provide

better performance than the industry-standard TPE used thus far.”

Certifications & Compliance

The new Medalist compounds are made with FDA-listed ingredients, are certified at a minimum to the ISO 10993-5 standard for biocompatibility, and are REACH SVHC compliant. They are free of DEHP and other phthalates, BPA, and latex. Standard grades are ADM-free.

Source: Teknor Apex Company

Tuesday, December 4, 2018

Scientists to combine ultrasonic, vibration and heat for flaw detection in aviation

Daria Derusova, JRF from the TPU Research School of High Energy

Physics is developing a system combining three methods of

non-destructive testing including a vibrational, resonant ultrasonic and

thermal ones to test composites for aviation applications.

This approach is of interest for aviation and automobile industries as it will make it possible to monitor the quality of complex and large-sized products made of composite materials taking into account their physical properties. The Russian Science Foundation has supported this two-year project up to 2020.

The project manager Daria Derusova says ‘Every year, new composite materials appear and they challenge existing methods of non-destructive testing. Joints between the materials are of particular complexity and importance.’

Now classic ultrasonic and X-ray testing are used at the production.

The latter is the most accurate but it does not fit to large-sized objects that are presented in aviation a lot. In turn, ultrasonic facilities consume kilowatts of electricity to stimulate materials with a mono-frequency acoustic signal. Laser vibrometry in the combination with resonant stimulation of defects is seen as the most promising modern method. Such an approach allows activating local resonant vibration in the area of damage that also causes the increase of temperature in this area. In turn, an infrared camera will allow the registration of the temperature change and the addition of data about the quality of products. As a result, we expect to build a laboratory facility to test large and complex objects by form.

Meantime, it will consume several times less electricity than high-power ultrasonic installations. The developed approach will be an alternative to the existing methods of non-destructive testing in aviation and machine-building industry,’ says the early-career researcher.

The facility will comprise of such elements as resonant ultrasonic stimulation using piezoelectric transducers, a scanning laser Doppler vibrometer and an infrared camera with specialized software.

‘The essence of the system is that a tested object – material is exposed to acoustic stimulation in a wide range of frequencies.

Elastic waves create vibrations of both material itself and its inhomogeneities. The resonant frequency of vibrations of defects’ walls differs from that of the object that can be detected with a scanning vibrometer. In addition, due to intense resonant vibrations defect areas are locally heated. We register these changes with an infrared camera. The data of quality testing allow us to identify a defect itself, its location, form, and size,’ clarifies Daria Derusova.

In the framework of this project, TPU scientists cooperate with peers from the Institute of Strength Physics and Materials Science SB RAS (Laboratory for Quality Testing of Materials and Structures), the University of L'Aquila (Italy) and the Symbiosis Institute of Technology (India). The S.А. Chaplygin Siberian Research Institute of Aviation (SibNIA, Novosibirsk) provides samples of materials for testing proposed technology.

Source: www.tpu.ru

This approach is of interest for aviation and automobile industries as it will make it possible to monitor the quality of complex and large-sized products made of composite materials taking into account their physical properties. The Russian Science Foundation has supported this two-year project up to 2020.

The project manager Daria Derusova says ‘Every year, new composite materials appear and they challenge existing methods of non-destructive testing. Joints between the materials are of particular complexity and importance.’

Now classic ultrasonic and X-ray testing are used at the production.

The latter is the most accurate but it does not fit to large-sized objects that are presented in aviation a lot. In turn, ultrasonic facilities consume kilowatts of electricity to stimulate materials with a mono-frequency acoustic signal. Laser vibrometry in the combination with resonant stimulation of defects is seen as the most promising modern method. Such an approach allows activating local resonant vibration in the area of damage that also causes the increase of temperature in this area. In turn, an infrared camera will allow the registration of the temperature change and the addition of data about the quality of products. As a result, we expect to build a laboratory facility to test large and complex objects by form.

Meantime, it will consume several times less electricity than high-power ultrasonic installations. The developed approach will be an alternative to the existing methods of non-destructive testing in aviation and machine-building industry,’ says the early-career researcher.

The facility will comprise of such elements as resonant ultrasonic stimulation using piezoelectric transducers, a scanning laser Doppler vibrometer and an infrared camera with specialized software.

‘The essence of the system is that a tested object – material is exposed to acoustic stimulation in a wide range of frequencies.

Elastic waves create vibrations of both material itself and its inhomogeneities. The resonant frequency of vibrations of defects’ walls differs from that of the object that can be detected with a scanning vibrometer. In addition, due to intense resonant vibrations defect areas are locally heated. We register these changes with an infrared camera. The data of quality testing allow us to identify a defect itself, its location, form, and size,’ clarifies Daria Derusova.

In the framework of this project, TPU scientists cooperate with peers from the Institute of Strength Physics and Materials Science SB RAS (Laboratory for Quality Testing of Materials and Structures), the University of L'Aquila (Italy) and the Symbiosis Institute of Technology (India). The S.А. Chaplygin Siberian Research Institute of Aviation (SibNIA, Novosibirsk) provides samples of materials for testing proposed technology.

Source: www.tpu.ru

Thursday, November 29, 2018

Saertex wins JEC Asia Award 2018 and AVK Award for use of Saertex Leo materials in Deutsche Bahn’s ICE-3 fleet

The Saertex Leo series stands for optimum fire protection in rail

transport, the marine market or the construction industry. For the

renovation of the floor panels in 66 trains of the ICE fleet of the

Deutsche Bahn with fireproof Saertex Leo materials, Saertex received two

awards.

On November 5th, Saertex was awarded 3rd place at the AVK Award in the Products/Applications category for its project at the International Composites Congress (ICC) in Stuttgart. In addition, the entry won 1st place in the Railways category at the JEC Asia Innovation Award, which was presented on November 15th at the JEC Asia trade fair in Seoul, Korea.

The Saertex Leo composite system meets the high HL2 fire protection requirements in R10 in accordance with EN 45545 for use in rail vehicles. In contrast to conventional fire protection systems, Leo does not negatively influence mechanical parameters. The Leo system consists of four components, with SAERfoam as the core material, an NFC layer of fiberglass, special Leo infusion resins and a Leo protection layer as the finish.

Saertex Leo thus meets international fire protection standards in the rail vehicle, shipbuilding and construction industries with regard to flame propagation and smoke development. Compared to conventionally manufactured components, the Leo laminates offer impressive mechanical properties and, in the case of the floor panels in the ICE-3 fleet, 50 percent less weight. Train floors are frequently exposed to moisture not only in snowy regions; as opposed to the materials used up to now, the material components contained in the Leo system do not rot.

Source:Saertex

On November 5th, Saertex was awarded 3rd place at the AVK Award in the Products/Applications category for its project at the International Composites Congress (ICC) in Stuttgart. In addition, the entry won 1st place in the Railways category at the JEC Asia Innovation Award, which was presented on November 15th at the JEC Asia trade fair in Seoul, Korea.

The Saertex Leo composite system meets the high HL2 fire protection requirements in R10 in accordance with EN 45545 for use in rail vehicles. In contrast to conventional fire protection systems, Leo does not negatively influence mechanical parameters. The Leo system consists of four components, with SAERfoam as the core material, an NFC layer of fiberglass, special Leo infusion resins and a Leo protection layer as the finish.

Saertex Leo thus meets international fire protection standards in the rail vehicle, shipbuilding and construction industries with regard to flame propagation and smoke development. Compared to conventionally manufactured components, the Leo laminates offer impressive mechanical properties and, in the case of the floor panels in the ICE-3 fleet, 50 percent less weight. Train floors are frequently exposed to moisture not only in snowy regions; as opposed to the materials used up to now, the material components contained in the Leo system do not rot.

Source:Saertex

Wednesday, November 28, 2018

New Medical-grade PEEK & PPSU Filaments by Solvay for Additive Manufacturing

Solvay

has broadened its portfolio of high-performance filaments for premium

additive manufacturing (AM) applications with the introduction of three

medical grade products for use in the healthcare industry.

A neat KetaSpire® polyetheretherketone (PEEK) AM filament (NT1 HC) and a 10-percent carbon fiber reinforced KetaSpire® PEEK AM filament (CF10 HC), together with a neat Radel® polyphenylsulfone (PPSU) AM filament (NT1 HC) are Solvay’s first medical grade AM filaments for limited contact applications (<24hr bodily="" br="" contact="" fluid="" tissue="">

Christophe Schramm, Additive Manufacturing business manager at Solvay’s Specialty Polymers global business unit (GBU), said:

“The healthcare industry is quickly emerging as a leading market to benefit from AM technology which makes customized parts for single use or low volumes possible. However, there is still a very limited choice of high-performance filaments that meet the stringent regulatory requirements in healthcare and this is the gap we want to close with our new selection of medical grade products.”

Jeff Hrivnak, global business manager for Healthcare at Solvay’s Specialty Polymers GBU, said:

“These new medical grade AM filaments emphasize Solvay’s continuing, pro-active initiatives to support our customers. The filaments can be used for a range of healthcare applications such as patient-specific cutting guides for surgery and for complex components in single-use and reusable medical devices.”

® KetaSpire and Radel are registered trademarks of Solvay.

Source: Solvay

Medical-grade AM Filaments

A neat KetaSpire® polyetheretherketone (PEEK) AM filament (NT1 HC) and a 10-percent carbon fiber reinforced KetaSpire® PEEK AM filament (CF10 HC), together with a neat Radel® polyphenylsulfone (PPSU) AM filament (NT1 HC) are Solvay’s first medical grade AM filaments for limited contact applications (<24hr bodily="" br="" contact="" fluid="" tissue="">

Christophe Schramm, Additive Manufacturing business manager at Solvay’s Specialty Polymers global business unit (GBU), said:

“The healthcare industry is quickly emerging as a leading market to benefit from AM technology which makes customized parts for single use or low volumes possible. However, there is still a very limited choice of high-performance filaments that meet the stringent regulatory requirements in healthcare and this is the gap we want to close with our new selection of medical grade products.”

KetaSpire® PEEK & Radel® PPSU AM Filaments

- Solvay’s KetaSpire® PEEK AM filaments are designed to allow excellent fusion of printed layers, enable high part density and deliver exceptional part strength, including along the z-axis.

- Radel® PPSU AM filaments also provide excellent fusion of printed layers in addition to transparency, high elongation and toughness.

Jeff Hrivnak, global business manager for Healthcare at Solvay’s Specialty Polymers GBU, said:

“These new medical grade AM filaments emphasize Solvay’s continuing, pro-active initiatives to support our customers. The filaments can be used for a range of healthcare applications such as patient-specific cutting guides for surgery and for complex components in single-use and reusable medical devices.”

® KetaSpire and Radel are registered trademarks of Solvay.

Source: Solvay

Friday, November 23, 2018

Stora Enso Acquires Cellutech, a Wood-based Components Manufacturer

Stora

Enso has increased its ownership up to 100% in Cellutech AB. The

company specializes in the development of new materials and applications

based on cellulose, micro-fibrillated cellulose (MFC) and other

wood-based components.

Replacing Fossil-based Materials with Renewable Ones

The

acquisition of Cellutech supports Stora Enso’s vision of replacing

fossil-based materials with renewable ones originating from wood. The

acquired company works, among others, in the areas of foams for

packaging and hydroponics where the markets are continuously growing.

Cellulosic foams can, for example, be used in packaging to replace

polystyrenes which are the most widely used plastics.

Adding a New Dimension to Fiber and Cellulose Capabilities

“The

acquisition of Cellutech will add a new dimension to our fiber and

cellulose capabilities particularly in lightweight cellulose foams and

spheres. We are investing in technologies and expertise that will

further broaden application development competence in Stora Enso’s

Biomaterials Division,” says Markus Mannström, EVP, Stora Enso

Biomaterials.

Established in 2013, Cellutech is an agile team of eight scientists and

researchers serving as a link between academia and industry. Cellutech

was formed to take world class scientific research developed at SweTree

Technologies and Wallenberg Wood Science Center and develop the ideas

into commercially successful technologies and products.

The transaction will not have a material financial impact on the Group.

The transaction will not have a material financial impact on the Group.

Source:Stora Enso

Wednesday, November 21, 2018

New Copolyester Filaments to Advance FDM 3D Printing by ElogioAM at Formnext 2018

ElogioAM B.V., a newly formed Joint Venture between Swedish Perstorp AB

and Dutch 3D4Makers B.V, continues to introduce its new filament

solutions to advance FDM additive manufacturing.

Following its breakthrough, easy to print Facilan™ C8 delivering

superior finish, mechanical properties and minimum post-processing for

demanding prototyping, models and spare parts, ElogioAM now introduce

its new addition, Facilan HT.

FDM Additive Manufacturing requires more durable and high strength materials to take full benefits of 3D printing. PLA and PET are of limited use for durable application due to their relatively low temperature resistance while ABS suffers of warping and relatively low strength.

Like all Facilan products, it is designed to easily be printed on most conventional FDM printers available with minimum warping. It is fully amorphous and enables the production of translucent parts in the z direction. FacilanHT has been extensively tested during its development and the feedback has been very positive.

Matthew Forrester, 3D printing Tech leader L`Oréal, France, said:

“Excellent technical support from the Elogio team, Facilan HT is as easy to print as PLA, with a good level of translucidity, perfect for our prototyping needs.”

Nomura Toshihito, J-Techno Inc. Digital Manufacturing Systems, Japan, said:

“Facilan HT is excellent; it is printing with no warping and good stability.”

Dick Potharst, Multi-3dPrint, the Netherlands, said:

“I tested Facilan HT on the DDDrop and the Ultimaker, very easy to print with and nice glossy shine.”

Imants Treidis, CEO, Mass Portal, Latvia, said:

“We are proud to work together with ElogioAM and showcase the Facilan HT at our booth. The material has great potential for applications where exceptional stability and simple printing process is a requirement.”

Facilan HT is being showcased at Formnext, November 13-18th, 2018 on 3D printer manufacturer Mass Portal Booth stand 3.1 H89.

Source: ElogioAM B.V.

Designed to Overcome Common Product Limitations

FDM Additive Manufacturing requires more durable and high strength materials to take full benefits of 3D printing. PLA and PET are of limited use for durable application due to their relatively low temperature resistance while ABS suffers of warping and relatively low strength.

- Facilan HT is designed to address those common product limitations and specifically designed for 3D printing.

- It is safe copolyester with high temperature resistance with heat deflection temperature of 89°C.

- Its high stiffness enables design optimization for faster rigid part print jobs.

Like all Facilan products, it is designed to easily be printed on most conventional FDM printers available with minimum warping. It is fully amorphous and enables the production of translucent parts in the z direction. FacilanHT has been extensively tested during its development and the feedback has been very positive.

Facilan HT - Great Potential

|

| 3D Printed Coffee Cup Model from Facilan™ HT |

“Excellent technical support from the Elogio team, Facilan HT is as easy to print as PLA, with a good level of translucidity, perfect for our prototyping needs.”

Nomura Toshihito, J-Techno Inc. Digital Manufacturing Systems, Japan, said:

“Facilan HT is excellent; it is printing with no warping and good stability.”

Dick Potharst, Multi-3dPrint, the Netherlands, said:

“I tested Facilan HT on the DDDrop and the Ultimaker, very easy to print with and nice glossy shine.”

Imants Treidis, CEO, Mass Portal, Latvia, said:

“We are proud to work together with ElogioAM and showcase the Facilan HT at our booth. The material has great potential for applications where exceptional stability and simple printing process is a requirement.”

ElogioAM at Formnext 2018

Facilan HT is being showcased at Formnext, November 13-18th, 2018 on 3D printer manufacturer Mass Portal Booth stand 3.1 H89.

Source: ElogioAM B.V.

Tuesday, November 20, 2018

Ashland to Sell its Composites Business in Germany to INEOS Enterprises for USD 1.1 Bn

Ashland Global Holdings Inc.

has recently announced that it has signed a definitive agreement to

sell its Composites business and the butanediol (BDO) manufacturing

facility in Marl, Germany, to INEOS Enterprises

in a transaction valued at approximately $1.1 billion. The transaction

is expected to close prior to the end of the June 2019 quarter,

contingent on certain customary regulatory approvals, standard closing

conditions and completion of required employee information and

consultation processes.

Ashland expects net proceeds from the sale to total approximately $1 billion and anticipates that proceeds primarily will be used for debt reduction. Prior to reporting its financial results for the first quarter of fiscal 2019, Ashland plans to update its outlook for both the first quarter and for the full 2019 fiscal year to reflect the impact of moving these businesses to discontinued operations.

Ashland's Composites unit is among the global leader in unsaturated polyester resins, vinyl ester resins and gel coats, while the BDO facility in Germany and related merchant products included in the agreement are part of Ashland's Intermediates and Solvents (I&S) segment. Ashland's Composites and Marl BDO facility have combined sales of more than $1.1 billion per year and approximately 1,300 employees. Ashland will retain its BDO plant in Lima, Ohio, to ensure consistent supply for the company's internal needs.

Bill Wulfsohn, Ashland chairman and chief executive officer, said:

"Composites and Marl are outstanding businesses with strong market positions and high-performing teams. At the same time, the divestiture of these businesses is consistent with Ashland's vision of becoming the premier specialty chemicals company. With a more streamlined and focused product portfolio, improved margins and reduced earnings volatility, Ashland will be better positioned to deliver sustained earnings growth and unlock significant value for shareholders. Over the past two years, we have taken specific actions to sustain and grow Ashland's premium mix while also improving our competitiveness, particularly within Specialty Ingredients. These actions are driving strong earnings growth, as evident in our fiscal 2018 financial results."

Privately owned INEOS is one of the world's largest manufacturers of chemicals and oil products, with annual sales of $60 billion and approximately 20,000 employees. The London-based company operates 171 sites in 24 countries.

Ashley Reed, CEO, INEOS Enterprises, said:

"We believe that the Ashland Composites business will have great potential for growth under INEOS ownership and we are looking forward to working with a great team of people who are determined to meet the developing needs of our customers."

Citi is acting as financial advisor to Ashland, and Squire Patton Boggs LLP is acting as legal advisor.

Source: Ashland Global Holdings Inc

Divestment to Become Premier in Chemical World

Ashland expects net proceeds from the sale to total approximately $1 billion and anticipates that proceeds primarily will be used for debt reduction. Prior to reporting its financial results for the first quarter of fiscal 2019, Ashland plans to update its outlook for both the first quarter and for the full 2019 fiscal year to reflect the impact of moving these businesses to discontinued operations.

Ashland's Composites unit is among the global leader in unsaturated polyester resins, vinyl ester resins and gel coats, while the BDO facility in Germany and related merchant products included in the agreement are part of Ashland's Intermediates and Solvents (I&S) segment. Ashland's Composites and Marl BDO facility have combined sales of more than $1.1 billion per year and approximately 1,300 employees. Ashland will retain its BDO plant in Lima, Ohio, to ensure consistent supply for the company's internal needs.

Placing itself in a Better Position

Bill Wulfsohn, Ashland chairman and chief executive officer, said:

"Composites and Marl are outstanding businesses with strong market positions and high-performing teams. At the same time, the divestiture of these businesses is consistent with Ashland's vision of becoming the premier specialty chemicals company. With a more streamlined and focused product portfolio, improved margins and reduced earnings volatility, Ashland will be better positioned to deliver sustained earnings growth and unlock significant value for shareholders. Over the past two years, we have taken specific actions to sustain and grow Ashland's premium mix while also improving our competitiveness, particularly within Specialty Ingredients. These actions are driving strong earnings growth, as evident in our fiscal 2018 financial results."

Privately owned INEOS is one of the world's largest manufacturers of chemicals and oil products, with annual sales of $60 billion and approximately 20,000 employees. The London-based company operates 171 sites in 24 countries.

Ashley Reed, CEO, INEOS Enterprises, said:

"We believe that the Ashland Composites business will have great potential for growth under INEOS ownership and we are looking forward to working with a great team of people who are determined to meet the developing needs of our customers."

Citi is acting as financial advisor to Ashland, and Squire Patton Boggs LLP is acting as legal advisor.

Source: Ashland Global Holdings Inc

Sunday, November 18, 2018

Turning Steel Mill Emissions into Useful Chemicals and Plastics - Nouryon & Tata Steel

Nouryon (formerly

AkzoNobel Specialty Chemicals), Tata Steel and the Port of Amsterdam

have joined together to study the feasibility of a large green hydrogen

cluster in the Amsterdam region. The three parties consider green

hydrogen as vital for reaching climate targets and building a more

circular economy, for example by combining it with emissions from steel

manufacture to make new products.

As a first step, the parties will study the feasibility of a 100

megawatt water electrolysis facility to produce up to 15,000 tons of

hydrogen per year as well as oxygen at Tata Steel’s IJmuiden site, near

Amsterdam. By using renewable electricity, the initial unit will enable a

carbon saving of up to 350,000 tons of CO2 per year,

equivalent to the emissions of more than 40,000 households. A final

investment decision is expected in 2021. The partner companies have the

ambition to further scale up the technology.

“Tata Steel is a strong supporter of hydrogen as a facilitator of the energy transition,” said Hans Fischer, CEO of Tata Steel Europe. “This project could be a stepping stone to make large quantities of affordable hydrogen available in the future to enable us to become a CO2 neutral steel producer.”

Source: Nouryon

Studying the Feasibility of Green Hydrogen Cluster

As a first step, the parties will study the feasibility of a 100

megawatt water electrolysis facility to produce up to 15,000 tons of

hydrogen per year as well as oxygen at Tata Steel’s IJmuiden site, near

Amsterdam. By using renewable electricity, the initial unit will enable a

carbon saving of up to 350,000 tons of CO2 per year,

equivalent to the emissions of more than 40,000 households. A final

investment decision is expected in 2021. The partner companies have the

ambition to further scale up the technology.

Nouryon will operate the facility, while Tata Steel will use the oxygen

to further enhance the sustainability of its production processes. The

parties will jointly explore different routes to use hydrogen for

turning steel mill emissions into useful chemicals and products. The

Port of Amsterdam will focus on the infrastructure for further

distribution of green hydrogen, which will be the basis for the

development of new industries and zero-emission transport in the

Amsterdam area.

Sustainable Chemical Industry

“This partnership builds on our existing initiatives to support the development of a sustainable chemical industry,” said Knut Schwalenberg, Managing Director Industrial Chemicals at Nouryon. “Green hydrogen is a realistic alternative for fossil-based raw materials and enables new forms of green chemistry, such as using steel mill gas, CO2, or waste to make plastics and move to new, circular value chains,” he said.“Tata Steel is a strong supporter of hydrogen as a facilitator of the energy transition,” said Hans Fischer, CEO of Tata Steel Europe. “This project could be a stepping stone to make large quantities of affordable hydrogen available in the future to enable us to become a CO2 neutral steel producer.”

Climate Neutral Circular Industry

Koen Overtoom, CEO Port of Amsterdam, added: “Large-scale production of green hydrogen, fueled by offshore wind, will enable the Amsterdam-North Sea canal region to make a leap forward towards a climate neutral circular industry. It will support our ambition towards synthetic fuels and synthetic kerosene and emission-free mobility.”CO2 Reduction Target of 49% by 2030

The recently presented Dutch Climate Law sets an ambitious CO2 reduction target of 49% by 2030 compared to 1990. The parties believe that green hydrogen can make a significant contribution towards this target and aim to reach sufficient scale to absorb all emissions from Tata Steel’s plant in IJmuiden and use it for the production of new materials. The development of the green hydrogen cluster will also enable emissions-free buses and heavy transport in the entire Amsterdam area.Source: Nouryon

Thursday, November 15, 2018

Hexagon Composites to Supply Compressed Hydrogen Tanks for FCEV Serial Production

Hexagon Composites will supply compressed hydrogen tanks for serial

production of fuel cell electric vehicles (FCEV) to be launched by an

automotive OEM.

Hexagon is currently developing the tanks to support anticipated production activities as early as the 2020 timeframe. Production is planned to run for at least five years. Hexagon estimates the combined value for development and serial production to be in the range of USD 50 to 70 million (approximately NOK 0.4 billion to 0.6 billion).

Rick Rashilla, Senior Vice President of Hexagon Composites' Hydrogen Automotive business, said:

"This is a major contract for Hexagon and for the growing FCEV industry. Hexagon Composites is committed to investing resources into the success of this project and for the adoption of Hydrogen in combination with fuel-cell technology as a low-carbon alternative fuel for mobility applications. This selection further confirms our leading position as a light duty hydrogen tank developer for the FCEV industry."

Supporting Anticipated Production Activities

Hexagon is currently developing the tanks to support anticipated production activities as early as the 2020 timeframe. Production is planned to run for at least five years. Hexagon estimates the combined value for development and serial production to be in the range of USD 50 to 70 million (approximately NOK 0.4 billion to 0.6 billion).

Rick Rashilla, Senior Vice President of Hexagon Composites' Hydrogen Automotive business, said:

"This is a major contract for Hexagon and for the growing FCEV industry. Hexagon Composites is committed to investing resources into the success of this project and for the adoption of Hydrogen in combination with fuel-cell technology as a low-carbon alternative fuel for mobility applications. This selection further confirms our leading position as a light duty hydrogen tank developer for the FCEV industry."

Third Automotive OEM Contract

Jack Schimenti, Executive Vice President of Hexagon Composites, said:

"We are pleased to secure yet another major contract from a leading OEM and maintaining market leadership based on our integrity, attention to safety and delivering to customer specifications. By receiving our third serial production commitment, it cements the value proposition and long-term potential we see in the hydrogen space."

Hydrogen is a clean and safe energy carrier that can be used as fuel for power in a wide range of applications, and can be easily stored on a large scale. The life cycling properties of all-composite pressure cylinders, with plastic liners and carbon fiber structure, make them more suitable for storage of hydrogen than metal lined alternatives.

Source: Hexagon Composites

Friday, November 9, 2018

China's Haiyuan to build a carbon fiber base for ultra-light NEVs in Zhejiang

Chinese company Haiyuan New Material Technology will build a carbon

fiber production base in eastern Zhejiang province to develop

ultra-light materials for new energy vehicles.Chinese company Haiyuan New Material Technology will build a carbon

fiber production base in eastern Zhejiang province to develop

ultra-light materials for new energy vehicles.

Regarding the new plant, Haiyuan signed a framework agreement with Zhejiang Sea Port, an investment firm set up by Zhejiang province's government, Shenzhen-listed Fujianese chemical firm's parent Haiyuan Composites Technology said in a statement to its stockholders. The company said that Haiyuan has designed a production line for ultra-light car bodies while securing intellectual property rights.

The investment firm will also establish a car industry fund for new material development, to which Haiyuan will invest in. The fund will have an initial investment of CNY2 billion (USD290 million) and later it will acquire a stake in the vehicle parts firm.

Both parties will promote the use of carbon fiber materials in cars to expand from Zhejiang to the whole country, while helping Haiyuan to become the leader in the sector, the statement added.

Regarding the new plant, Haiyuan signed a framework agreement with Zhejiang Sea Port, an investment firm set up by Zhejiang province's government, Shenzhen-listed Fujianese chemical firm's parent Haiyuan Composites Technology said in a statement to its stockholders. The company said that Haiyuan has designed a production line for ultra-light car bodies while securing intellectual property rights.

The investment firm will also establish a car industry fund for new material development, to which Haiyuan will invest in. The fund will have an initial investment of CNY2 billion (USD290 million) and later it will acquire a stake in the vehicle parts firm.

Both parties will promote the use of carbon fiber materials in cars to expand from Zhejiang to the whole country, while helping Haiyuan to become the leader in the sector, the statement added.

Friday, November 2, 2018

Cost-effective Way to Turn Food Waste into PHAs - U of T Scarborough

At U of T Scarborough, researchers have found a way to produce high

quality PHAs using food waste in a cost-effective way – while also

mitigating the effects of plastic pollution. PHAs have many benefits

over other forms of bio-plastics.

It’s no wonder that passion led Yu to team up with a talented group of scientists and engineers — many of whom are U of T students or alum — to form Genecis. The company uses recent advancements in biotechnology, microbial engineering and machine learning to take food destined for landfill and convert it into high quality, fully biodegradable plastics.

“More than $1 trillion worth of food is wasted globally every year. What we’re able to do is take this waste and turn it into something of higher value.”

Food waste is a significant environmental issue in North America, explains Yu. In the United States roughly 55 million tons of food is thrown away annually. Once that food hits landfill it generates methane, a greenhouse gas that’s 20 times more potent than carbon dioxide. In fact, it’s estimated that 34 per cent of methane emissions in the U.S. alone are caused by food waste.

“We feel that by using synthetic biology create high quality products out of this organic waste in a cost-effective way – while also mitigating the effects of plastic pollution – is really the way of the future,” she says.

Though only in her early 20s, this isn’t Yu’s first foray into entrepreneurship. She has more than six years’ experience, first at a start-up software company as an undergrad before moving to another start-up that converted restaurant food waste into biogas.

It was there that she met several talented engineers, learned about the microbiology of converting discarded food into other materials, and discovered a valuable lesson in the economics of re-using food waste.

“Converting food waste into biogas is not only a time-consuming process, the end product is fairly low value,” she says.

It was shortly after this experience that she connected with a fellow environmental science student in The Hub, U of T Scarborough’s entrepreneurial incubator, to figure out what else could be made from food waste.

“We looked at different types of bio-rubbers and bio-chemicals before landing on PHAs. We felt it had the biggest market potential.”

PHAs, or polyhydroxyalkanoates, are a type of polymer produced in nature by bacteria that have many benefits over other forms of bio-plastics. For one, it can be a thermoplastic, meaning it can be easily molded and remolded into different products. Another benefit is that, unlike many other forms of bio-plastics, it won’t ruin the recycling process.

“Many people throw bio-plastics into the recycling bin rather than the compost, but if it’s not a thermoplastic, it can’t be remolded,” says Yu.

“This disrupts the physical properties of new recycled products — they will end up falling apart.”

PHAs won’t cause this problem if it accidentally ends up in recycling bins, which makes it much easier for waste management companies to handle.

But what really sold Yu on PHAs is the fact that it’s fully biodegradable. PHAs degrade within one year in a terrestrial environment, and fewer than 10 years in marine environments. Meanwhile, synthetic plastics can take hundreds of years to degrade in similar environments.

Given its superior physical properties and the process it takes to create, Yu says Genecis’s PHAs are best suited for higher-end products like toys, flexible packaging, 3D-printing filament and medical applications including surgical staples, sutures and stints.

“The PHAs we create can be used to make pretty much anything, but it makes the most economic sense to use it in higher-quality, multi-use products,” she says.

While PHAs have been in the market for the past two decades, most come directly from corn and sugarcane crops. Yu explains that the process Genecis uses to create its PHAs is much cheaper because they avoid the expenses required to acquire their feedstock.

The process takes less than seven days from getting the food waste to having the purified plastic — making biogas, on the other hand, takes an average of 21 days. When the company opens its demonstration plant later next year, it will be able to convert three tons of organic waste into PHAs weekly.

While the process used by Genecis works for pretty much all types of food, some foods like simple carbs and proteins can be more efficiently converted, says Yu.

The company currently has two locations — their main lab in U of T’s Banting and Best Building, in the heart of Toronto’s Discovery District, and the other in the Environmental Science and Chemistry Building at U of T Scarborough, which is responsible for research and development.

In their downtown lab they work with pilot-scale bioreactors, and are continuing to scale up their operations with an industry partner to a demonstration plant by the end of next year. Meanwhile, their facility at UTSC houses smaller bioreactors that are used to help optimize their production process.

“We’re fine-tuning things to figure out the best conditions to operate our bacteria cultures,” says Vani Sankar, Genecis’s head of biotechnology and a postdoc at U of T Scarborough. “This includes what combinations of temperature, pH and amount of food will give us the best yield.”

In less than two years of operation, Genecis has already won more than $330,000 in prize money from start-up competitions. Yu says the support, guidance and mentorship they’ve received from the Hub, the Creative Destruction Lab, and the Hatchery, a start-up accelerator at U of T Engineering, has also been instrumental in their growth.

“I can’t say enough about the support I received from the Hub. It’s a great place to go for any students interested in starting their own company. I formed great partnerships with other students there and the mentorship I received was second to none,” Yu says. As Genecis aims to ramp up production, Yu says this support and the lessons learned from her work in other start-ups will be invaluable.

“Our goal is to create the highest value from organic waste,” says Yu, adding they’ve cultured and isolated hundreds of species of bacteria that currently don’t exist in databases.

“Soon we will be able to synthesize specialty chemicals and other materials from organic waste, all at a lower cost than traditional production methods using synthetic biology,” she says.

Those specialty chemicals can be used in a range of products including those found in cosmetics and the health and wellness industry, says Yu. “It’s a really exciting time for us.”

Source: U of T Scarborough

Three-step Process to Produce PHAs

|

| Developing materials from food waste |

Process

- Genecis uses a three-step process to produce its PHAs, explains Michael Williamson, the company’s head of mechanical engineering and U of T engineering grad.

- First, they use a mixture of anaerobic (without oxygen) bacteria that breaks down the food waste into volatile fatty acids, similar to how food is broken down in our stomachs.

- Next, the fatty acids are added to a mixed culture of aerobic (with oxygen) bacteria that are specially selected to produce PHAs in their cells.

- Finally, they use an extraction process to break open the cells, collect and purify the plastic.

It’s no wonder that passion led Yu to team up with a talented group of scientists and engineers — many of whom are U of T students or alum — to form Genecis. The company uses recent advancements in biotechnology, microbial engineering and machine learning to take food destined for landfill and convert it into high quality, fully biodegradable plastics.

“More than $1 trillion worth of food is wasted globally every year. What we’re able to do is take this waste and turn it into something of higher value.”

Food Waste - Significant Environmental Issue

Food waste is a significant environmental issue in North America, explains Yu. In the United States roughly 55 million tons of food is thrown away annually. Once that food hits landfill it generates methane, a greenhouse gas that’s 20 times more potent than carbon dioxide. In fact, it’s estimated that 34 per cent of methane emissions in the U.S. alone are caused by food waste.

“We feel that by using synthetic biology create high quality products out of this organic waste in a cost-effective way – while also mitigating the effects of plastic pollution – is really the way of the future,” she says.

Though only in her early 20s, this isn’t Yu’s first foray into entrepreneurship. She has more than six years’ experience, first at a start-up software company as an undergrad before moving to another start-up that converted restaurant food waste into biogas.

It was there that she met several talented engineers, learned about the microbiology of converting discarded food into other materials, and discovered a valuable lesson in the economics of re-using food waste.

“Converting food waste into biogas is not only a time-consuming process, the end product is fairly low value,” she says.

It was shortly after this experience that she connected with a fellow environmental science student in The Hub, U of T Scarborough’s entrepreneurial incubator, to figure out what else could be made from food waste.

“We looked at different types of bio-rubbers and bio-chemicals before landing on PHAs. We felt it had the biggest market potential.”

A Reusable, Biodegradable Form of Plastic

PHAs, or polyhydroxyalkanoates, are a type of polymer produced in nature by bacteria that have many benefits over other forms of bio-plastics. For one, it can be a thermoplastic, meaning it can be easily molded and remolded into different products. Another benefit is that, unlike many other forms of bio-plastics, it won’t ruin the recycling process.

“Many people throw bio-plastics into the recycling bin rather than the compost, but if it’s not a thermoplastic, it can’t be remolded,” says Yu.

“This disrupts the physical properties of new recycled products — they will end up falling apart.”

PHAs won’t cause this problem if it accidentally ends up in recycling bins, which makes it much easier for waste management companies to handle.

But what really sold Yu on PHAs is the fact that it’s fully biodegradable. PHAs degrade within one year in a terrestrial environment, and fewer than 10 years in marine environments. Meanwhile, synthetic plastics can take hundreds of years to degrade in similar environments.

Given its superior physical properties and the process it takes to create, Yu says Genecis’s PHAs are best suited for higher-end products like toys, flexible packaging, 3D-printing filament and medical applications including surgical staples, sutures and stints.

“The PHAs we create can be used to make pretty much anything, but it makes the most economic sense to use it in higher-quality, multi-use products,” she says.

While PHAs have been in the market for the past two decades, most come directly from corn and sugarcane crops. Yu explains that the process Genecis uses to create its PHAs is much cheaper because they avoid the expenses required to acquire their feedstock.

The process takes less than seven days from getting the food waste to having the purified plastic — making biogas, on the other hand, takes an average of 21 days. When the company opens its demonstration plant later next year, it will be able to convert three tons of organic waste into PHAs weekly.

While the process used by Genecis works for pretty much all types of food, some foods like simple carbs and proteins can be more efficiently converted, says Yu.

The company currently has two locations — their main lab in U of T’s Banting and Best Building, in the heart of Toronto’s Discovery District, and the other in the Environmental Science and Chemistry Building at U of T Scarborough, which is responsible for research and development.

U of T Start-up

In their downtown lab they work with pilot-scale bioreactors, and are continuing to scale up their operations with an industry partner to a demonstration plant by the end of next year. Meanwhile, their facility at UTSC houses smaller bioreactors that are used to help optimize their production process.

“We’re fine-tuning things to figure out the best conditions to operate our bacteria cultures,” says Vani Sankar, Genecis’s head of biotechnology and a postdoc at U of T Scarborough. “This includes what combinations of temperature, pH and amount of food will give us the best yield.”

In less than two years of operation, Genecis has already won more than $330,000 in prize money from start-up competitions. Yu says the support, guidance and mentorship they’ve received from the Hub, the Creative Destruction Lab, and the Hatchery, a start-up accelerator at U of T Engineering, has also been instrumental in their growth.

“I can’t say enough about the support I received from the Hub. It’s a great place to go for any students interested in starting their own company. I formed great partnerships with other students there and the mentorship I received was second to none,” Yu says. As Genecis aims to ramp up production, Yu says this support and the lessons learned from her work in other start-ups will be invaluable.

“Our goal is to create the highest value from organic waste,” says Yu, adding they’ve cultured and isolated hundreds of species of bacteria that currently don’t exist in databases.