The transparent injection molded 0.2-mm-thick outer shell of this dental device is made of Udel® P-1700 polysulfone (PSU) resin from Solvay Advanced Polymers, which is insert molded with a polycaprolactone (PCL) thermoplastic. To customize the GrindGuardN according to your mouth, it can be placed in a microwaved water for 90-120 seconds at 130°F (54.44°C). The white colored polycaprolactone turns transparent which signifies that it is soft enough to fit easily in synchronization with the front teeth. Polycaprolactone doesn’t deform or melt even at temperature up to 171°F (77.22°C). GrindGuardN, has received clearance from the U.S. Food & Drug Administration.

Thursday, November 25, 2010

Polysulfone Dental Device Remedies Teeth Grinding Problem

Monday, November 22, 2010

Researchers Train Bacteria to Convert High Percentage of Bio-wastes into Plastic

TU Delft Researcher Jean-Paul Meijnen has 'trained' bacteria to convert all the main sugars in vegetable, fruit and garden waste efficiently into high-quality environmentally friendly products such as bioplastics. There is considerable interest in bioplastics nowadays. The technical problems associated with turning potato peel into sunglasses, or cane sugar into car bumpers, have already been solved. The current methods, however, are not very efficient: only a small percentage of the sugars can be converted into valuable products. By adapting the eating pattern of bacteria and subsequently training them, Meijnen has succeeded in converting sugars into processable materials, so that no bio-waste is wasted.

Basis for bioplastics

The favored raw materials for such processes are biological wastes left over from food production. Lignocellulose, the complex combination of lignin and cellulose present in the stalks and leaves of plants that gives them their rigidity, is such a material. Hydrolysis of lignocellulose breaks down the long sugar chains that form the backbone of this material, releasing the individual sugar molecules. These sugar molecules can be further processed by bacteria and other micro-organisms to form chemicals that can be used as the basis for bioplastics. The fruit of the plant, such as maize, can be consumed as food, while the unused waste such as lignocellulose forms the raw material for bioplastics.

Cutting the price of the process

"Unfortunately, the production of plastics from bio-wastes is still quite an expensive process, because the waste material is not fully utilized," explains Jean-Paul Meijnen. (It should be noted here that we are talking about agricultural bio-wastes in this context, not the garden waste recycled by households.) The pre-treatment of these bio-wastes leads to the production of various types of sugars such as glucose, xylose and arabinose. These three together make up about eighty per cent of the sugars in bio-waste.

The problem is that the bacteria Meijnen was working with, Pseudomonas putida S12, can only digest glucose but not xylose or arabinose. As a result, a quarter of the eighty per cent remains unused. "A logical way of reducing the cost price of bioplastics is thus to 'teach' the bacteria to digest xylose and arabinose too."

Enzymes

The xylose has to be 'prepared' before Pseudomonas putida S12 can digest it. This is done with the aid of certain enzymes. The bacteria are genetically modified by inserting specific DNA fragments in the cell; this enables them to produce enzymes that assist in the conversion of xylose into a molecule that the bacteria can deal with.

Meijnen achieved this by introducing two genes from another bacterium (E. coli) which code for two enzymes that enable xylose to be converted in a two-stage process into a molecule that P. putida S12 can digest.

Evolution

This method did work, but not very efficiently: only twenty per cent of the xylose present was digested. The modified bacteria were therefore 'trained' to digest more xylose. Meijnen did this by subjecting the bacteria to an evolutionary process, successively selecting the bacteria that showed the best performance.

"After three months of this improvement process, the bacteria could quickly digest all the xylose present in the medium. And surprisingly enough, these trained bacteria could also digest arabinose, and were thus capable of dealing with the three principal sugars in bio-wastes." Meijnen also incorporated other genes, from the bacterium Caulobacter crescentus. This procedure also proved effective and efficient from the start.

Blend

Finally, in a separate project Meijnen succeeded in modifying a strain of Pseudomonas putida S12 that had previously been modified to produce para-hydroxybenzoate (pHB), a member of the class of chemicals known as parabens that are widely used as preservatives in the cosmetics and pharmaceutical industries.

Meijnen tested the ability of these bacteria to produce pHB, a biochemical substance, from xylose and from other sources such as glucose and glycerol. He summarized his results as follows: "This strategy also proved successful, allowing us to make biochemical substances such as pHB from glucose, glycerol and xylose. In fact, the use of mixtures of glucose and xylose, or glycerol and xylose, gives better pHB production than the use of unmixed starting materials. This means that giving the bacteria pretreated bio-wastes as starting material stimulates them to make even more pHB."

Sunday, November 21, 2010

Scientists Manipulate Plant Metabolism to Produce Potential Precursor to Raw Material for Plastics

Thursday, November 18, 2010

LCA by Toyota Tsusho & Braskem Concludes that Green Polyethylene can Reduce GHG Emission

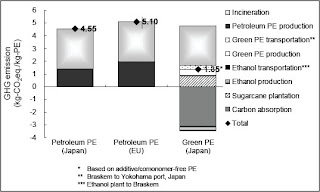

Braskem S.A. and Toyota Tsusho Corporation (Toyota Tsusho) have concluded the joint study of life cycle analysis for polyethylene derived from Brazilian sugarcane (Green Polyethylene), and has found that the Green Polyethylene emits less greenhouse gas (GHG) when compared to petroleum-based polyethylene even if it is delivered to the other side of the earth.

The University of Tokyo, Tokyo, Japan conducted the analysis under the collaborative study with the parties using the preliminary eco-efficiency study performed by Fundação Espaço Eco in Brazil (2007/2008), which shows that 1 kilogram of Green Polyethylene emits 1.35 kilograms* of CO2 equivalents of GHG when it is produced in Brazil, shipped to Japan, used by consumer as container and packaging, and then incinerated. Meanwhile, traditional petroleum-based polyethylene emits 4.55 to 5.10 kilograms in its overall life cycle. As a result, the study demonstrates that 70 to 74 percent of GHG can be reduced with the substitution of Green Polyethylene for traditional polyethylene.

For details of the study, Professor Masahiko Hirao and Assistant Professor Yasunori Kikuchi of the university will deliver a presentation at "International Congress on Sustainability Science and Engineering - ICOSSE11", the most renowned environmental congress held in Tucson, AZ, USA, on January 11, 2011.

Earlier this year, Braskem inaugurated the largest industrial-scale plant of bio-based ethylene with an annual production capacity of 200,000 tons to be converted into the same volume of Green Polyethylene. Toyota Tsusho will start distribution of Green Polyethylene in Asian countries including Japan after certain shipping time from Brazil to the countries.

Wednesday, November 17, 2010

Nobel Laureates from Manchester University Give Graphene a Teflon Makeover

Professor Andre Geim, who along with his colleague Professor Kostya Novoselov won the 2010 Nobel Prize for graphene - the world's thinnest material, has now modified it to make fluorographene - a one-molecule-thick material chemically similar to Teflon.

Fluorographene is fully-fluorinated graphene and is basically a two-dimensional version of Teflon, showing similar properties including chemical inertness and thermal stability. The results have been reported in the advanced online issue of the journal Small. The work is a large international effort and involved research groups from China, the Netherlands, Poland and Russia.

The team hopes that fluorographene, which is a flat, crystal version of Teflon and is mechanically as strong as graphene, could be used as a thinner, lighter version of Teflon, but could also be in electronics, such as for new types of LED devices.

Graphene, a one-atom-thick material that demonstrates a huge range of unusual and unique properties, has been at the centre of attention since groundbreaking research carried out at The University of Manchester six years ago. Its potential is almost endless - from ultrafast transistors just one atom thick to sensors that can detect just a single molecule of a toxic gas and even to replace carbon fibers in high performance materials that are used to build aircraft.

Professor Geim and his team have exploited a new perspective on graphene by considering it as a gigantic molecule that, like any other molecule, can be modified in chemical reactions. Teflon is a fully-fluorinated chain of carbon atoms. These long molecules bound together make the polymer material that is used in a variety of applications including non-sticky cooking pans.

To get fluorographene, the Manchester researchers first obtained graphene as individual crystals and then fluorinated it by using atomic fluorine. To demonstrate that it is possible to obtain fluorographene in industrial quantities, the researchers also fluorinated graphene powder and obtained fluorographene paper.

Fluorographene turned out to be a high-quality insulator which does not react with other chemicals and can sustain high temperatures even in air. One of the most intense directions in graphene research has been to open a gap in graphene's electronic spectrum, that is, to make a semiconductor out of metallic graphene. This should allow many applications in electronics. Fluorographene is found to be a wide gap semiconductor and is optically transparent for visible light, unlike graphene that is a semimetal.

Professor Geim said: "Electronic quality of fluorographene has to be improved before speaking about applications in electronics but other applications are there up for grabs."

Rahul Nair, who led this research for the last two years and is a PhD student working with Professor Geim, added: "Properties of fluorographene are remarkably similar to those of Teflon but this is not a plastic. "It is essentially a perfect one-molecule-thick crystal and, similar to its parent, fluorographene is also mechanically strong. This makes a big difference for possible applications.

"We plan to use fluorographene as an ultra-thin tunnel barrier for development of light-emitting devices and diodes. "More mundane uses can be everywhere Teflon is currently used, as an ultra-thin protective coating, or as a filler for composite materials if one needs to retain the mechanical strength of graphene but avoid any electrical conductivity or optical opacity of a composite".

Industrial scale production of fluorographene is not seen as a problem as it would involve following the same steps as mass production of graphene.

The Manchester researchers believe that the next important step is to make proof-of-concept devices and demonstrate various applications of fluorographene.

Professor Geim added: "There is no point in using it just as a substitute for Teflon. The mix of the incredible properties of graphene and Teflon is so inviting that you do not need to stretch your imagination to think of applications for the two-dimensional Teflon. The challenge is to exploit this uniqueness."

Tuesday, November 16, 2010

First turnkey CNG truck upfitted with vacuum body

Developed in collaboration with Vac-Con, the Freightliner Business Class M2 112V compressed natural gas unit will also be equipped with a CNG-powered auxiliary-mounted engine that powers the truck’s water system. Vac-Con provides combination sewer cleaners to municipal and private markets throughout the world.

Its combination cleaners combine high-pressure water and vacuum systems to effectively clean both sanitary and storm drainage infrastructure. Vac-Con tapped Freightliner Trucks to develop the CNG truck based on its ability to fulfill its unique specs and need for a turnkey chassis solution.

"There’s a tremendous green movement happening now, and our customers are looking to us to provide efficient products with alternative fuel options," said Tom Jody, marketing manager for Vac-Con. "From the beginning, the team at Freightliner Trucks had a genuine interest in this concept, and in its success.

" The truck will include an Allison 3000RDS transmission for optimum performance and efficiency, which include patented torque converter technology that results in improved startability at the launch of the vehicle, full power shifts, and a better performing engine. "The CNG project was truly a partnership and we look forward to continuing our work with Freightliner to further refine this and other natural gas products," Jody added. Freightliner Trucks is a division of Daimler Trucks North America LLC, headquartered in Portland, Oregon.

Tuesday, November 9, 2010

Thermoplastic Robot Suit Makes Aged Body Movement Easy

Carbon-Reinforced Ice Hockey Stick

Toyota Tsusho Signs a Bio-ethanol Offtake Agreement with Petrobras to Produce Bio-PET

Toyota Tsusho Corporation (TTC) recently concluded a long-term bio-ethanol offtake agreement with Petroleo Brasileiro S.A. (Petrobras), Brazilian national oil company.

Brazilian sugarcane ethanol will be used as feedstock in a chemical ethanol project that TTC is deploying with a local partner in Taiwan to produce Bio-PET. TTC agrees to procure sugar cane based bio-ethanol of approximately 1.4 million cubic meters for 10 years from 2012 and the contract is approximately 70 billion yen. This contracted bio-ethanol is supplied to TTC's bio PET business in Taiwan. This agreement will make establish the first global bio-PET integrated supply chain including, procurement of bio-ethanol, production of bio-mono ethylene glycol, tolling business of PET, and marketing of bio-PET.

Petrobras foresees investment in the order of 18 trillion yen in the 2010-2014 business plan. Petrobras has affirmative strategy not only conventional oil and gas projects but also renewable energy including bio-fuel. This long-term offtake agreement is one of the actions to realize their strategy in the bio-fuel business.

This is also first major agreement for Petrobras. And it would establish bio-ethanol supply chain between Brazil and Asia. This agreement will strength partnership with Petrobras. TTC accelerate to expand renewable energy business and continue to strength bio-ethanol supply chain which contributes to lower-carbon society.

Suncor Energy Selects GE's Advanced 1.6 Megawatt Wind Turbines for its Wind Power Project

MONTREAL -- GE has announced an order from Suncor Energy for 55 of GE's advanced 1.6-megawatt wind turbines for one of the largest wind power projects in the province of Alberta, Canada. The Wintering Hills project is part of a new "crop" of wind farms being built across Canada with the help of GE's technical expertise and highly reliable wind turbine technologies.

"Winning this deal with Suncor illustrates how our wind turbine power enhancement technologies are making a difference for our customers' return on investment," said Victor Abate, Vice President-Renewable Energy for GE Power & Water. "Our proven track record in handling the most robust wind locations remains a key factor in our success."

GE's 1.6-megawatt wind turbine makes use of a range of product features - including 82.5-meter blades - to maximize power output while providing superior control flexibility and increased reliability with decreased maintenance requirements. The technology builds on GE's proven experience of its 1.5-megawatt turbine, the workhorse of the global wind energy industry with more than 14,000 units installed.

At peak operation, the Wintering Hills wind farm is expected to generate enough clean electricity to power approximately 35,000 Canadian homes.

The 88-megawatt Wintering Hills project is located near Drumheller, approximately 125 km (78 miles) northeast of Calgary. GE will deliver 55 of its advanced wind turbines to the site beginning in the second quarter of 2011. The project is owned jointly by Suncor (70%) and Teck Resources (30%).

"Alberta is rich in many resources that can be used to produce electricity, including wind energy," said Keith Triginer, GE Energy's newly appointed country executive for Canada. "We are working hand-in-hand with Suncor and others to make wind and other alternative energy sources a larger, more integral part of the Province's overall energy supply."

Demand Increases for Cereplast's Bioplastic Resin Post Italian Ban on Petroleum-Based Plastic Bags

Thursday, November 4, 2010

Natural gas on the rise

At the Fiat stand, the focus was on Natural Power models. In addition to the German premiere of the 136-hp Fiat Doblò, the gas variants of the Fiorino and Ducato were also on display. VW focussed on the completely revised Caddy, which utilises the tried and tested natural gas engine from its predecessor, while Opel presented the Combo CNG. Furthermore, Renault Trucks was represented by the "Clean Tech" label, a new brand that combines environmentally-friendly models with alternative drive systems such as natural gas. The Stralis CNG was also one of the vehicles presented by Iveco at IAA.

Volvo Trucks was the talk of this year’s IAA with its Volvo FM. The truck’s 13-liter engine is special in that it can be run on biogas as well as diesel, thus taking advantage of both technologies, according the Swedish OEM. Moreover, efficiency has been increased by 30 to 40 percent compared to previous gas engines.

A world-first was on display at the stand of MBtech, a Mercedes Benz subsidiary. In the "Reporter" concept study a natural gas engine and an electric motor were combined in a plug-in full-hybrid solution. Both engines can operate independently. Of special interest to local authorities was the concept study presented by Hako, who displayed a Fumo fitted with an Iveco natural gas engine. This 3-litre engine produces 100 kW or 136 hp, and meets the EEV exhaust standard.

Tuesday, November 2, 2010

Coca-Cola trials LBM for use in delivery vehicles

The soft drinks company is running tests of a 21-tonne Iveco Stralis vehicle run on liquid biomethane, which is produced by Gasrec. The fuel is created by extracting naturally occurring methane from organic waste in landfill sites.

Gasrec’s fuel is now being used by major household names in the UK, including Waitrose (which announced in August 2010 that it will run an initial five home delivery vehicles on LBM); Sainsbury’s (which uses Gasrec’s liquid biomethane for a number of its dual-fuel vehicles); and Tesco which runs 25 home delivery vehicles on the fuel.

Richard Lilleystone, CEO of Gasrec, stated: “Some of the biggest companies in the world are showing a real commitment to reducing CO2. Transport is often the biggest problem for them. But now, there is a real sustainable alternative to diesel for fleet vehicles. The performance of biomethane in vehicles far outstrips that of electricity. We hope that this step will be the beginning of a larger deployment for Coca-Cola Enterprises. It is apparent that growing numbers of like-minded organisations are electing to use biomethane as a fuel of choice which is good news for the environment and for local air quality”.

Liquid biomethane reduces CO2, gives a much higher vehicle performance than electric vehicles and has a similar fuel consumption pattern to diesel. Refueling stations are being provided to CCE’s Enfield depot by Gasrec’s infrastructure partner, Gas Container Services (GCS).

The natural gas produced from biomass in landfill is then converted to liquid biomethane, has the lowest carbon footprint of all the renewable vehicles and is commercially competitive against diesel and petrol. The LBM is then used to fuel dedicated gas-powered or duel-fuel vehicles.

Monday, November 1, 2010

PMMA-Based Racing Car Windshield

The material is said to have a lower infrared transmission than glass which consequently helps keeping the passenger compartment comfortably cooler. This aside, PMMA is also been used in side and rear windows, roof panels, and more. Lotus Exige body parts made of CFK and ROHACELL® structural foam and plastic charge air ducts were fitted in the car engine.

Today's KNOWLEDGE Share : The Value Inside Food Waste

Today's KNOWLEDGE Share The Value Inside Food Waste Food waste is often seen as disposal — yet it is actually displaced resources. One ...

-

Envalior launches new PPS compounding facility in Uerdingen, Germany. New facility supports growing demand for Xytron™ in Europe and the Ame...

-

Today's KNOWLEDGE Share What Is Going Wrong in UK Plastics Recycling? Biffa shut its Sunderland plant. Viridor walked away from Avonmout...

-

Today's KNOWLEDGE Share “Robotic 3D printing can compete with traditional boatbuilding”, Simone Barbera and Mattia De Santis, Caracol V...