Genomatica and Asahi Kasei announce a strategic partnership to commercialize renewably-sourced nylon 6,6 made from Genomatica’s bio-based HMD (hexamethylenediamine, also abbreviated as HMDA) building block. Asahi Kasei looks to this partnership to support its goal to be first-to-market with a more sustainable nylon 6,6 for the automotive and electronics industries, based on plant-based HMD, and to accelerate the achievement of its corporate sustainability objectives.

Genomatica’s Sustainable HMD

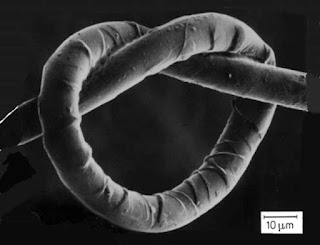

HMD is a key component of nylon 6,6 (also known as polyamide 6,6) and multiple other types of nylon, with a global market of 2 million tons per year. Conventional HMD is made starting from fossil fuels, such as crude oil or natural gas. Renewably sourced HMD made with Genomatica’s technology is derived from renewable feedstocks, such as plant-based sugars, and can improve the sustainability of the many materials made from it.

Genomatica develops complete, integrated process and manufacturing plant designs that use biotechnology, fermentation, and renewable feedstocks to make widely-used ingredients and materials with lower carbon footprints. Asahi Kasei expects Genomatica’s innovation to help the company reach its goal of becoming carbon neutral by 2050.

GENO™ HMD Process Technology

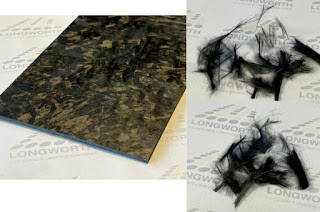

Building upon Genomatica’s recently announced breakthrough to successfully produce significant volumes of plant-based HMD, Asahi Kasei intends to apply the GENO™ HMD process technology to make more sustainable materials for use in products such as high-temperature automotive parts, electronics, or yarns to produce airbags. Asahi Kasei will have preferential access to early volumes of renewably sourced HMD and perform nylon application testing, leveraging Asahi Kasei’s deep experience developing successful nylon applications. Asahi Kasei anticipates licensing Genomatica’s GENO™ HMD process technology to commercialize bio-based nylon 6,6.

“Just as the sustainable energy transition is reinventing how we power our lives, we are at the start of a sustainable material's transition that will reinvent the products we use every day and where they come from,” said Christophe Schilling, Genomatica CEO. “Genomatica’s partnership with Asahi Kasei utilizing the GENO™ HMD process for nylon 6,6 and other specialty nylons marks another important step forward in this transition and leads the way toward more renewably-sourced, bio-based manufacturing plants replacing those utilizing fossil fuels.”

Source: Genomatica