Researchers Develop Nanobio-Hybrid Microbes Capable of Converting CO2 Into Plastics

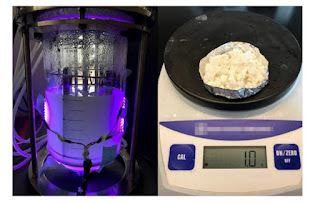

CU Boulder researchers have developed nanobio-hybrid organisms capable of using airborne carbon dioxide and nitrogen to produce a variety of plastics and fuels, a promising first step toward low-cost carbon sequestration and eco-friendly manufacturing for chemicals. “Living Factories” that Eat Harmful CO 2 By using light-activated quantum dots to fire particular enzymes within microbial cells, the researchers were able to create “living factories” that eat harmful CO 2 and convert it into useful products such as biodegradable plastic, gasoline, ammonia and biodiesel. “The innovation is a testament to the power of biochemical processes,” said Prashant Nagpal, lead author of the research and an assistant professor in CU Boulder’s Department of Chemical and Biological Engineering. “We’re looking at a technique that could improve CO 2 capture to combat climate change and one day even potentially replace carbon-intensive manufacturing for plastics and fuels.” Nanoscopic Quant